Choosing the right decking material for commercial or residential projects is a big decision—especially when balancing long-term durability, appearance, and return on investment. Real wood has been the traditional choice for decades, but wood look fiber cement decking is quickly becoming a preferred option for many contractors, architects, and developers.

If you're weighing these two materials, here's a closer look at how they compare in terms of longevity, value, and overall performance.

Durability in the Long Run

Wood decking, whether it’s pressure-treated pine, cedar, or tropical hardwood, faces constant exposure to moisture, UV rays, insects, and rot. Over time, even high-quality wood can warp, splinter, or crack. To preserve its integrity, wood needs consistent maintenance—sealing, staining, and replacing damaged boards.

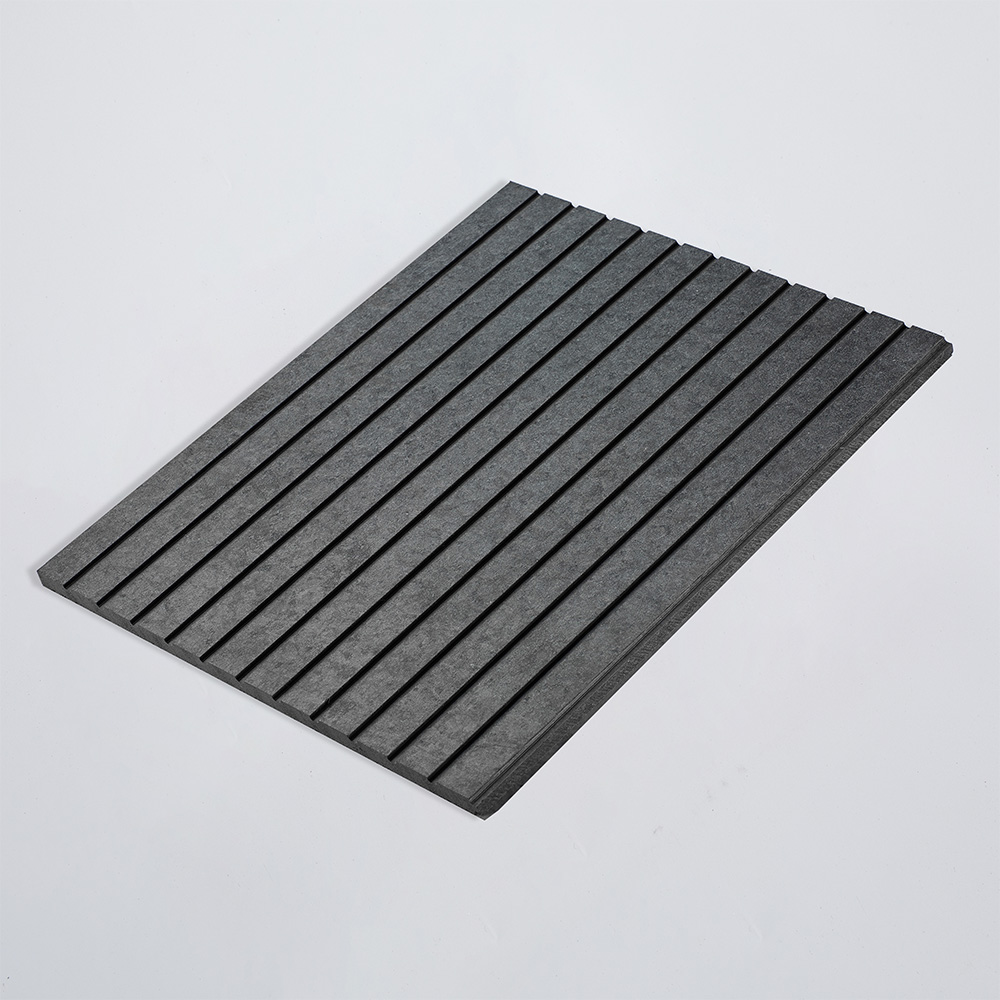

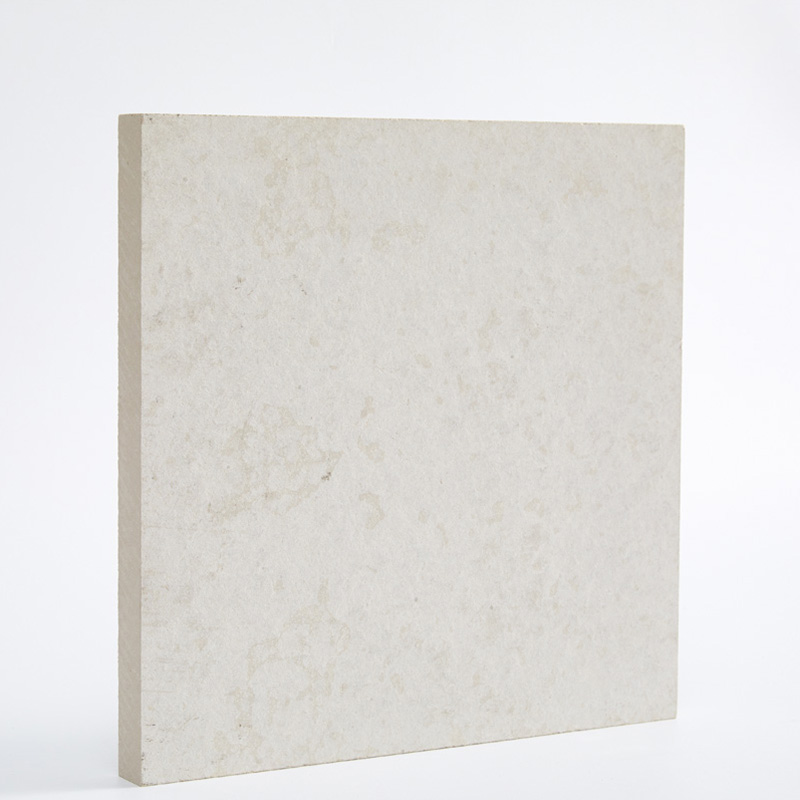

Fiber cement decking, on the other hand, is engineered for performance. Manufactured from a blend of cement, cellulose fibers, and additives, it stands up to harsh weather conditions, fire, pests, and daily wear. For large-scale projects like public walkways, commercial patios, or multifamily residential spaces, this resistance translates to fewer repairs and longer service life.

Simply put, fiber cement boards offer a level of reliability that real wood struggles to match over the long haul.

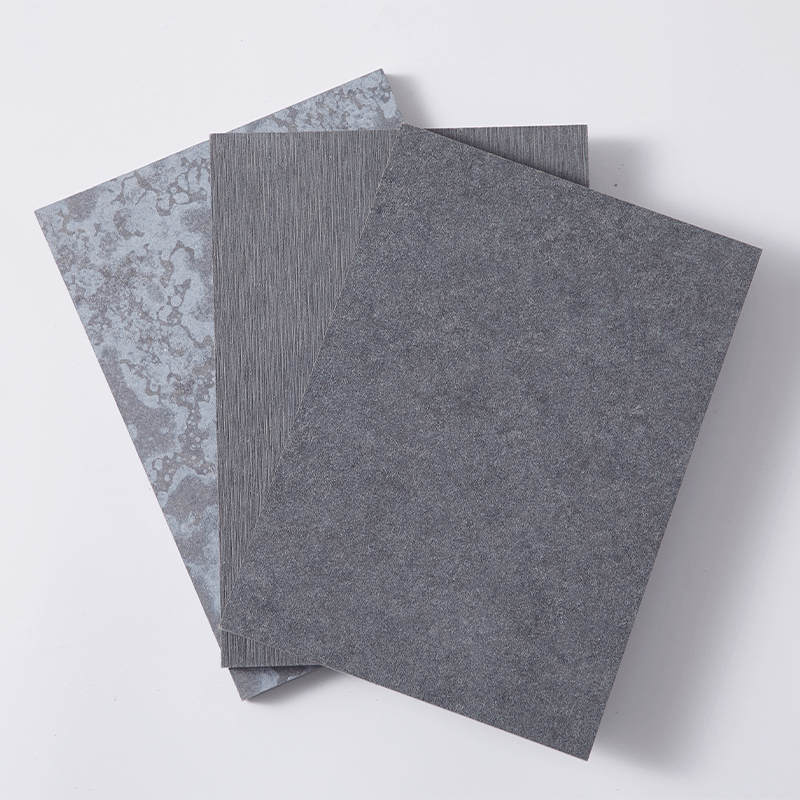

Wood Grain Fiber Cement Decking

Realistic Wood Appearance Without the Drawbacks

Many designers and project owners want the natural texture and warmth of wood, but not the problems that come with it. This is where wood look fiber cement really shines.

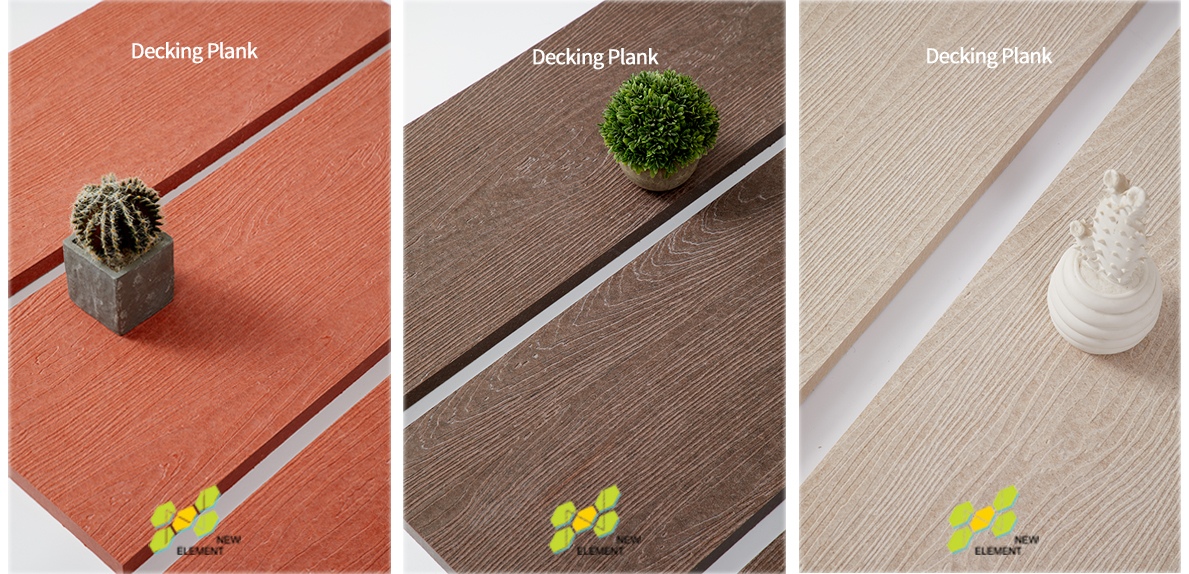

Modern fiber cement board manufacturers—like New Element—use advanced embossing and finishing techniques to replicate authentic wood grain. The result? Fiber cement board wood finish options that capture the richness of oak, cedar, or walnut, without the inconsistencies or fading.

Unlike wood, which can develop uneven tones or discolor over time, wood-look fiber cement maintains its aesthetic with minimal effort. No sanding, no refinishing—just a stable, attractive surface year after year.

Maintenance: Minimal vs. Demanding

When it comes to upkeep, real wood demands attention. It needs to be cleaned regularly, resealed or repainted every few years, and checked for signs of decay or insect damage. These ongoing costs, in both time and materials, can add up significantly—especially on large installations.

Fiber cement decking, by contrast, is virtually maintenance-free. Routine cleaning with soap and water is typically all it takes. It doesn’t need sealing, and it won’t attract termites or mold. That kind of low-maintenance appeal is a major reason more builders are specifying fiber cement decking in both commercial and high-end residential projects.

Fire Resistance and Safety

For decks in wildfire-prone areas or near fire-sensitive structures, material choice can be a safety issue as well as an aesthetic one. Real wood, even treated varieties, remains combustible.

Fiber cement boards are non-combustible and meet stringent fire safety codes, making them a reliable choice for hotels, apartment complexes, restaurants, and public buildings. This fire resistance can also support insurance compliance and reduce risk on job sites.

Wood-Look Fiber Cement Decking Plank

Cost Comparison Over Time

While wood may seem cheaper at the outset, the ongoing expenses tied to maintenance, repairs, and eventual replacement quickly change the equation. Factor in labor costs for sealing or board replacement, and the price difference begins to favor fiber cement.

Wood look fiber cement decking provides greater long-term value. Its extended lifespan, resistance to damage, and lower maintenance requirements create significant savings over a 10–20 year period. For project developers looking at lifecycle cost—not just initial outlay—it’s often the smarter investment.

Sustainability: Better Use of Resources

There’s also the environmental consideration. Logging for natural wood contributes to deforestation and habitat disruption. Even sustainable forestry practices carry a carbon footprint.

Fiber cement products are manufactured using abundant and recyclable materials. Many fiber cement board suppliers also follow environmentally responsible practices, and fiber cement boards are built to last longer—reducing the need for replacement and waste.

In green building projects where LEED certification or sustainable sourcing matters, fiber cement is a more conscious choice.

Fiber Cement Decking With Wood Finish

Applications for Commercial & Residential Projects

Fiber cement decking is finding increasing traction across a variety of applications:

- Commercial outdoor seating areas

- Hotel balconies and rooftop lounges

- Retail storefront walkways

- Residential decks and pool surrounds

- Public parks and recreation zones

Because of its stability and consistent finish, fiber cement board wood finish products are easy to integrate with modern architectural designs and other cladding systems. The flexibility of design with the resilience of cement makes it ideal for large-scale use.

Wood Look Fiber Cement Decking For Public Parks

Final Thoughts

Real wood still has its appeal, especially in small-scale or traditional projects. But when longevity, fire safety, cost-efficiency, and low maintenance are key, wood look fiber cement decking has a clear advantage. It gives project owners the appearance of natural timber with significantly fewer complications—and that combination of aesthetics and performance is hard to beat.

For builders and buyers who prioritize long-term value, it’s worth looking beyond the surface. Fiber cement may just be the better bet for your next project. Explore New Element’s outdoor wood grain decking—designed to deliver the natural beauty of wood with the strength and stability of fiber cement. Ideal for commercial and residential use, it’s the smart choice when performance matters.

Fiber Cement Board Wood Finish