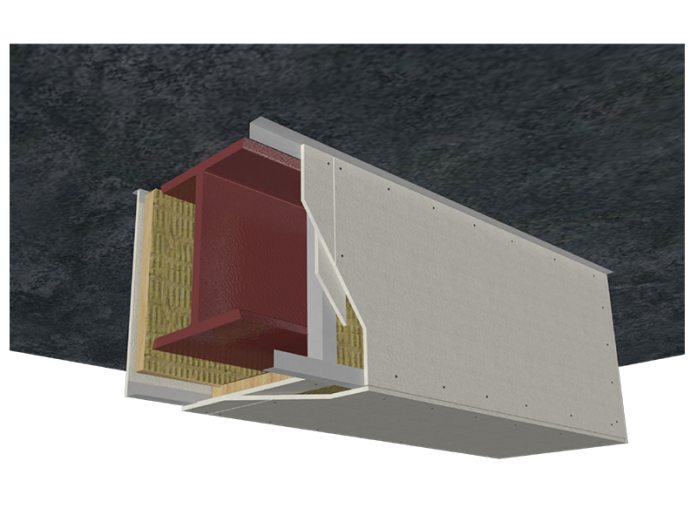

Structural steel is widely used in commercial and industrial construction due to its strength and versatility. However, steel is vulnerable to fire, corrosion, and thermal expansion, which can compromise structural integrity and safety. Choosing the right structural steel protection system is crucial to prevent these risks. To understand why New Element's calcium silicate boards are a reliable solution, it helps to first explore what a structural steel protection system is and how it works.

What Is a Structural Steel Protection System?

A structural steel protection system works by insulating steel from heat and delaying temperature rise during a fire. By reducing heat transfer, these systems help prevent structural collapse and maintain building safety. Fire-resistant boards, including calcium silicate boards, are among the most effective materials for this purpose.

Structural Steel Protection System For Buildings

Common Pain Points in Structural Steel Protection Systems

Rapid Temperature Rise During Fires: Steel loses its strength quickly when exposed to high heat. Without proper insulation, a fire can cause steel beams to bend or collapse within minutes, posing safety hazards, casualties and costly repair needs.

Difficult Installation and Labor Costs: Many traditional fireproofing methods are heavy, hard to cut, or require specialized labor. This increases installation time and overall project cost.

Long-Term Durability Concerns: Some materials degrade over time, are susceptible to pests, or lose their protective properties in humid or high-temperature environments. This results in frequent maintenance and replacement costs.

Thermal Conductivity Issues: High thermal conductivity in protection boards can allow heat to reach the steel quickly, reducing fire-resistance performance and compromising safety.

Dimensional Instability: Boards that expand, warp, or shrink under changing conditions can be difficult to install correctly, leading to gaps in protection and reduced effectiveness.

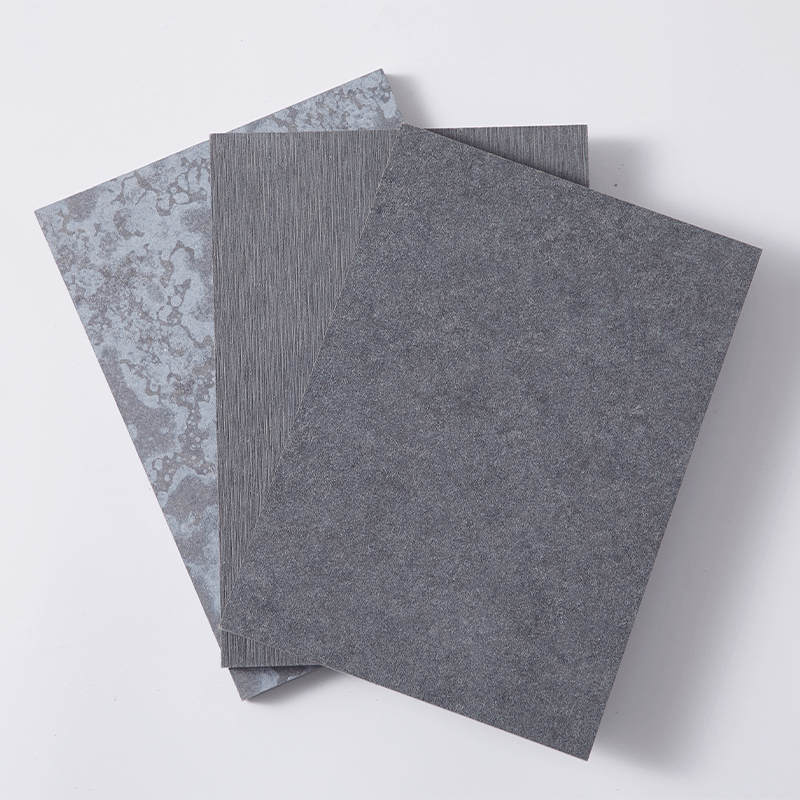

Calcium Silicate Board Manufacturer in China

How New Element Calcium Silicate Boards Solve These Problems

1. High-Temperature Resistance Up to 1200°C

New Element's Protectpan calcium silicate boards can withstand extreme temperatures, delaying steel temperature rise and preventing structural collapse during a fire. This directly addresses the primary concern of fire safety for steel structures.

2. Proven Fire Resistance for 2–4 Hours

In addition to high-temperature resistance, the Protectpan system delivers 2–4 hours of certified fire resistance. This extended protection time allows safe evacuation and effective emergency response, significantly reducing risks to both lives and structures.

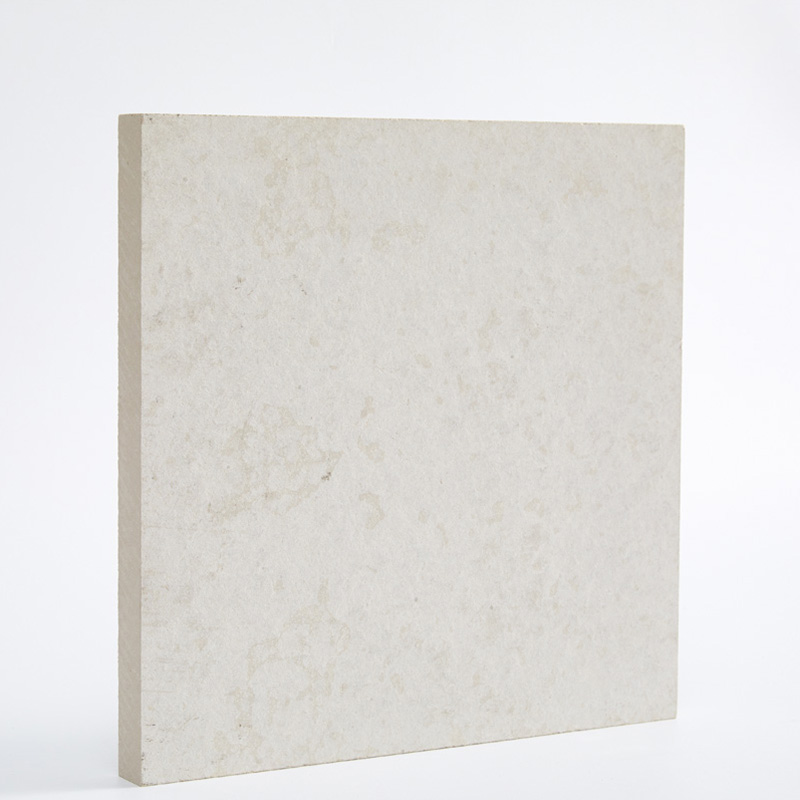

3. Lightweight and Easy to Handle

Unlike heavy, difficult-to-install boards, New Element's boards are lightweight and easy to cut on-site. This reduces labor time and costs, solving the common pain point of installation difficulties.

4. Durable and Pest-Resistant

The boards are resistant to wear, impact, moisture, and pests like moths. Their long-term durability ensures that steel protection remains effective over the years, reducing maintenance and replacement costs.

5. Low Thermal Conductivity

By minimizing heat transfer, calcium silicate boards maintain consistent temperature between the steel and its environment, enhancing fireproof performance and contributing to energy efficiency.

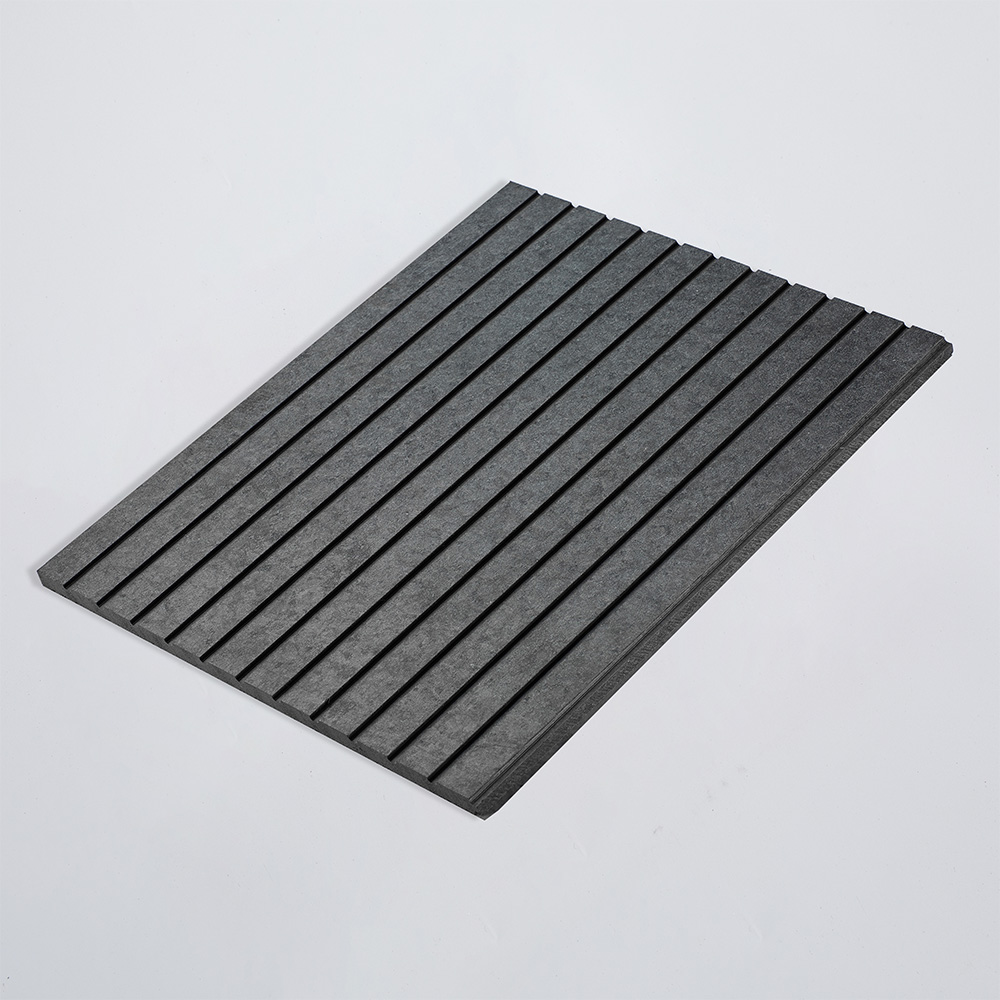

6. Stable Dimensions for Reliable Installation

Advanced manufacturing ensures boards maintain their shape and size, even under changing environmental conditions. This solves the problem of dimensional instability, ensuring complete and continuous protection for steel structures.

Specifications for Large-Scale Projects

• Sizes: 2440mm x 1220mm, 3050mm x 1220mm

• Thickness: Various options depending on structural requirements

• Low Density: Easy handling without sacrificing fire protection

These features make the boards suitable for industrial plants, commercial buildings, and high-temperature construction areas where steel protection is critical.

Calcium Silicate Boards for Structural Steel Protection System

Applications of Calcium Silicate Boards

• Industrial facilities exposed to heat or fire risks

• Commercial construction projects with fire protection requirements

• Large-scale infrastructure needing long-term durability

• Areas requiring efficient thermal insulation

Typical application scenarios include super high-rise buildings and skyscrapers, shopping malls, office buildings, hotels, and large public facilities, as well as transportation hubs such as railway and metro stations, power plants, nuclear facilities, petrochemical industries, data centers, and precision electronics manufacturing plants, where fire safety and thermal stability are critical.

Conclusion

Investing in New Element calcium silicate boards provides peace of mind. They solve critical pain points such as fire vulnerability, installation complexity, material degradation, and thermal inefficiency. With high-temperature resistance, durability, ease of handling, and stable dimensions, these boards deliver effective protection for steel structures in commercial and industrial projects.

Take the next step in safeguarding your steel structures today — contact New Element to learn at [email protected] how our calcium silicate boards can be integrated into your project, request a quote, or schedule a technical consultation with our experts.