In construction and renovation projects, choosing the right subflooring material plays a critical role in the long-term performance and durability of a building. Among the many options available today, the fiber cement flooring system has emerged as a modern, reliable alternative to traditional subflooring materials like plywood, OSB (oriented strand board), and concrete. But how does it compare in terms of strength, durability, cost-effectiveness, and installation?

In this article, we’ll compare the fiber cement flooring system to traditional subflooring solutions, helping contractors, architects, and project managers determine which option is better suited for their needs.

What Is a Fiber Cement Flooring System?

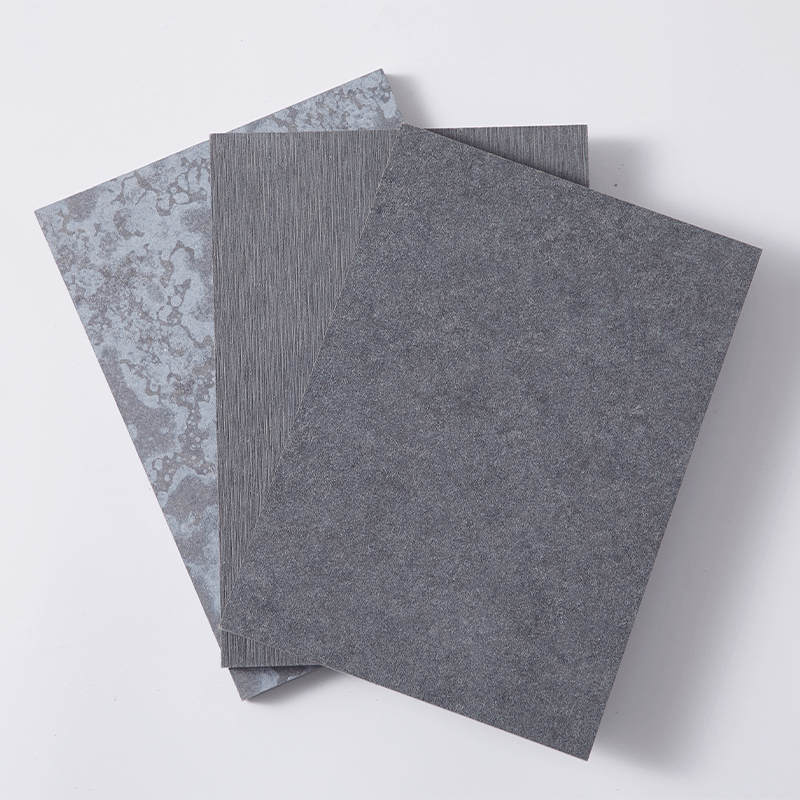

A fiber cement flooring system is composed of fiber cement boards that are specially engineered for use as floor slabs and underlayment. These boards are made by blending cement with cellulose fibers and other additives, resulting in a dense, durable material ideal for high-impact and moisture-prone environments.

Whether it’s for residential, commercial, or industrial construction, fiber cement floor slabs offer a versatile solution for modern building demands.

Fiber Cement Flooring System Manufacturer in China

Fiber Cement Flooring System: Key Advantages

1. Exceptional Moisture Resistance

Traditional plywood and OSB subflooring are prone to warping and swelling when exposed to water. In contrast, fiber cement boards are highly resistant to moisture, making them ideal for bathrooms, kitchens, laundry rooms, and other wet areas. Their ability to retain shape and integrity over time gives them a strong edge in humid or flood-prone environments.

2. Structural Integrity & Safety

Fiber cement floor slabs provide excellent structural stability, making them ideal for multi-story buildings and heavy-load applications. Their non-combustible composition ensures no toxic gas emissions, enhancing overall building fire safety.

3. Surface Flatness & Finish Flexibility

With superior flatness and surface durability, fiber cement flooring can be easily finished with floor coatings, rubber flooring, or wood overlays. This makes them a highly adaptable subfloor solution that balances design freedom with long-term performance.

4. Superior Load-Bearing Capacity

Fiber cement flooring systems are built to withstand heavy loads, making them suitable for both residential and commercial buildings. Their rigid, dense structure provides reliable support, even in high-traffic areas or where heavy equipment is used.

5. Easy Installation with Long-Term Performance

Many modern fiber cement boards are designed for easy installation using standard tools. They can be cut, drilled, and fastened just like wood, but without the risks of splitting or decay. Once installed, fiber cement flooring systems require minimal maintenance and remain dimensionally stable over time.

How Does Traditional Subflooring Compare?

Plywood and OSB

These wood-based panels have been widely used in subflooring for decades. They are lightweight, relatively easy to install, and cost-effective. However, they come with several limitations:

- Vulnerability to Moisture: Plywood and OSB tend to swell, delaminate, or rot when exposed to moisture.

- Fire Risk: These materials are combustible and can contribute to fire spread.

- Susceptibility to Termites and Mold: Being organic, they are more likely to harbor mold or be damaged by pests.

Concrete Subflooring

Concrete is another traditional option that offers strength and durability, but it has its own challenges:

- Heavy Weight: Concrete adds a significant load to the structure, which may not be suitable for all buildings.

- Cracking: Over time, concrete can crack due to shifting or temperature changes.

- Difficult Installation: Concrete subfloors require specialized labor and longer curing times, delaying construction schedules.

Cost Comparison: Fiber Cement vs. Traditional Subflooring

While fiber cement board may have a slightly higher upfront cost compared to plywood or OSB, its long-term benefits outweigh the initial investment. Its durability, moisture resistance, and minimal maintenance requirements translate into reduced replacement and repair costs over time.

In commercial applications, where downtime due to flooring failure can result in significant losses, investing in a fiber cement flooring system is a smart financial decision.

Applications of Fiber Cement Floor Slabs

- Hospitality & Institutional Use: Perfect for hotels, serviced apartments, school dormitories, and other commercial lodging or educational facilities.

- Industrial Facilities: Can withstand heavy machinery and foot traffic.

- Prefabricated Homes and Modular Buildings: A Lightweight yet strong flooring solution.

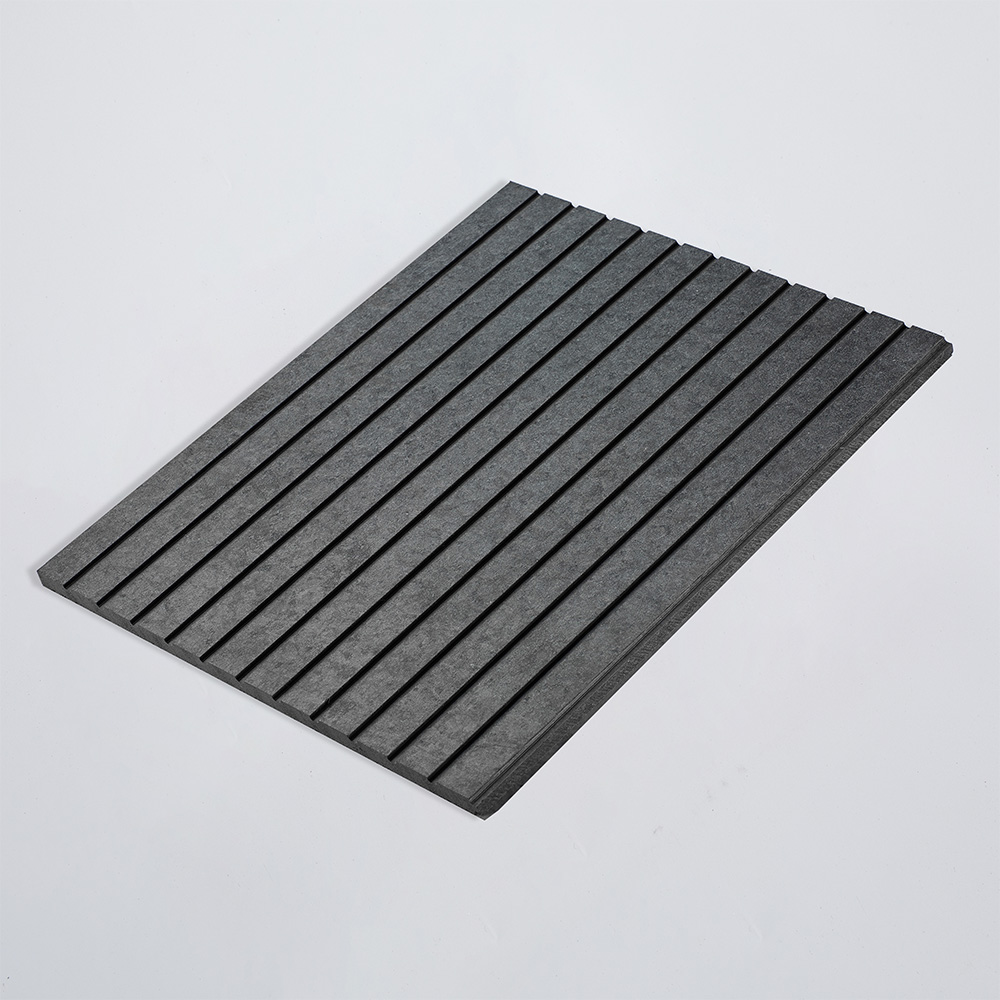

Indoor Fiber Cement Floor Slabs

Why More Builders Are Switching to Fiber Cement Flooring Systems

The global construction industry is rapidly evolving, and so are its materials. Increasing demand for fire-safe, eco-friendly, and high-performance building solutions has driven more builders to adopt fiber cement flooring systems.

When compared side-by-side, it’s clear that fiber cement board outperforms traditional subflooring in almost every key area — moisture resistance, fire safety, durability, and structural reliability. As sustainability and safety continue to drive construction standards worldwide, fiber cement floor slabs stand out as the superior choice.

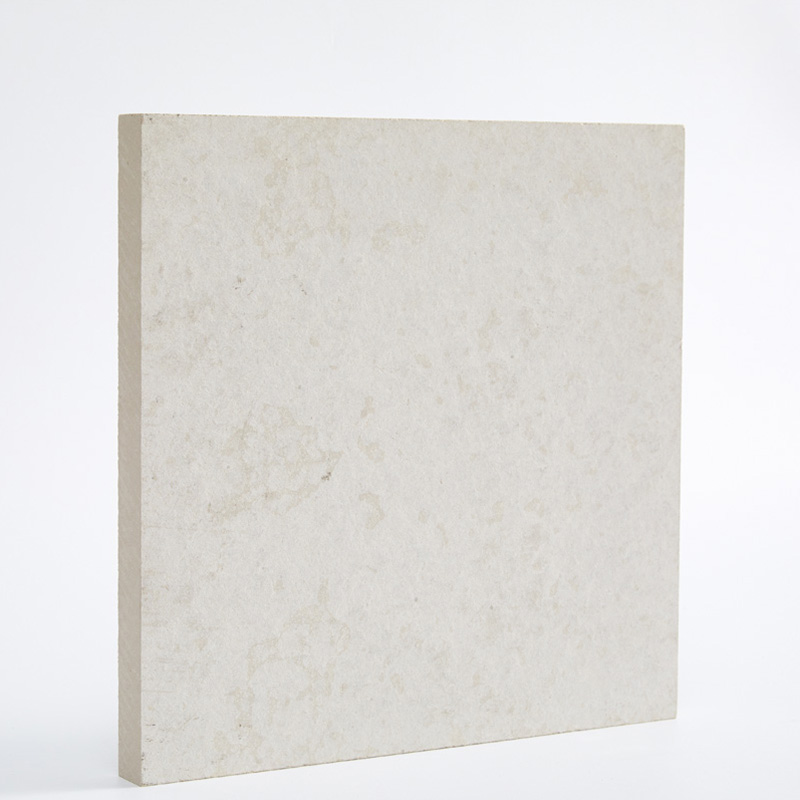

New Element Fiber Cement Flooring Systems

For builders seeking a high-performance alternative to traditional subflooring, New Element’s Floorslaber fiber cement board is a superior choice. Specifically engineered for modern flooring applications, the Floorslaber is a durable, strong, and lightweight fiber cement floor slab that ensures superior flatness and easy installation.

With low moisture movement and immunity to permanent water damage, this 24mm-thick fiber cement board flooring is ideal for wet and humid environments. Its anti-high-temperature and anti-crack properties ensure long-term structural stability, even under extreme conditions. Unlike traditional wood-based materials, Floorslaber is non-combustible and releases no toxic gases, providing peace of mind in terms of fire safety.

What sets Floorslaber apart is its resistance to chemicals, fungus, bacteria, insects, and vermin—making it not only durable but also hygienic. It is also highly versatile, and compatible with floor coatings, rubber flooring, and wood floors, allowing for seamless integration into various design finishes.

Fiber Cement Board Flooring - Floorslaber

As a lightweight alternative to concrete slabs, Floorslaber enables simple, fast, and clean installation, which reduces labor time and cost—an advantage especially beneficial in large-scale or prefabricated projects.

Common applications include:

- Interlayer floor baseboards

- Prefab houses and modular homes

- Light steel villas

- Student apartments and dormitories

- Prefabricated modular bathrooms

To learn more or get the best pricing on our high-performance fiber cement floor slabs, please feel free to contact us at [email protected]. Choose Floorslaber to enhance the durability, safety, and efficiency of your next flooring project!