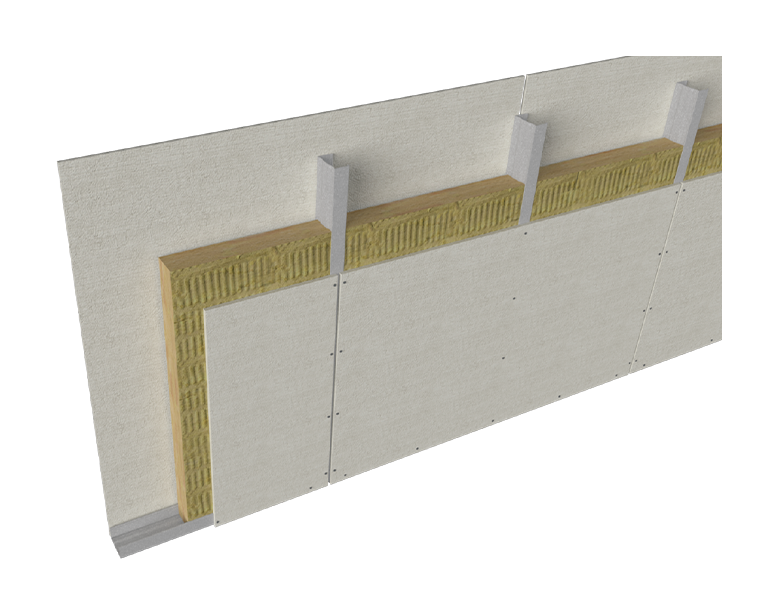

Designing a reliable fire partition system for a commercial building requires materials that can stand up to high temperatures, resist structural deformation, and maintain stable performance over long periods of use. Among the available fire-rated construction materials, calcium silicate boards have become a preferred choice for contractors, consultants, and project owners who need dependable passive fire protection. Their balance of fire resistance, durability, and installation efficiency makes them well-suited for modern fire safety requirements.

A fire partition system creates a barrier that slows the spread of flames and smoke from one area to another. By dividing a building into compartments, it provides essential evacuation time and reduces the overall impact of a fire. When such a system relies on a weaker material, its performance can decline under heat stress. This is the main reason why calcium silicate boards stand out—they are engineered to hold their form and function even under extreme temperatures.

Designed for High-Temperature Environments

For fire protection, temperature performance is the first benchmark. New Element's calcium silicate boards are built to withstand heat levels up to 1200°C, allowing them to remain structurally stable when exposed to severe fire conditions. This high level of resistance is especially valuable in applications such as fire partition walls, fire-rated ceilings, structural protection around beams, ducts, and shafts, and more high-temperature industrial zones.

A board material that maintains its structure under such conditions helps ensure the partition system continues to perform long enough for safe evacuation and fire control. This endurance is a key factor behind their use in demanding commercial and industrial projects.

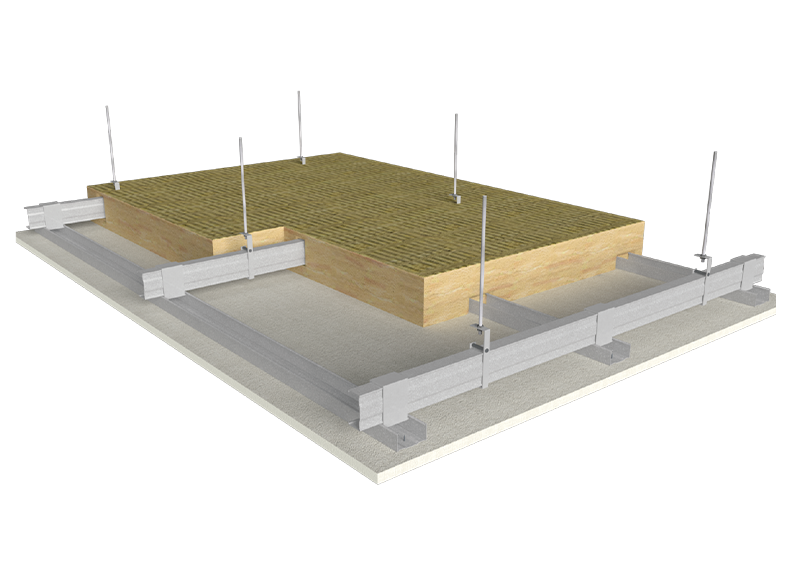

Calcium Silicate Boards For Fire Partition System

Lightweight & Easy to Cut for Faster Installation

In large commercial developments, installation speed and handling convenience can make a considerable difference in project timelines and labor costs. Calcium silicate boards from New Element are lightweight, making them easier to carry, position, and modify on site.

Their workable density allows clean cuts and customized shaping without specialized tools. For contractors managing tight schedules or working in complex spaces, this contributes to:

• Shorter installation cycles

• Reduced labor fatigue

• Lower transportation effort

• More precise detailing around pipes, corners, and openings

These practical benefits often help projects stay on schedule while maintaining a high standard of workmanship.

Durability & Resistance to Moths and Physical Wear

Fire partition systems must perform reliably for years, even in environments exposed to moisture, pests, or regular occupancy. Calcium silicate boards offer strong durability, standing up to impact and everyday wear. An added advantage is their mothproof nature—pests that commonly damage building materials do not affect them.

This longevity reduces the need for maintenance or replacement, which is especially important in shopping malls, hotels, office buildings, public facilities, industrial plants, and so on. Once installed, the boards maintain their integrity, helping building owners avoid unexpected repair costs.

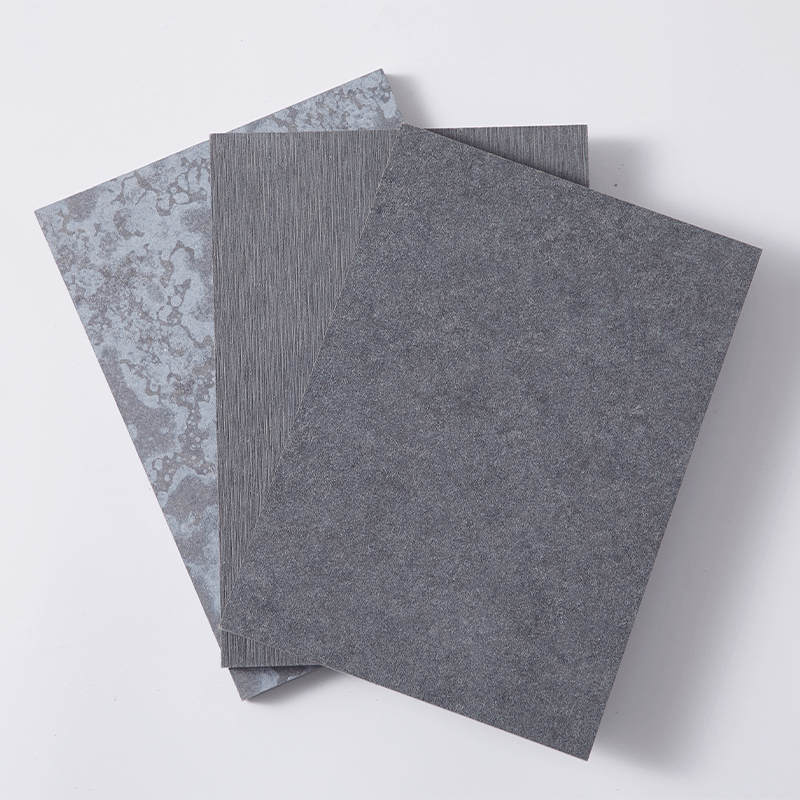

Calcium Silicate Board Manufacturer in China

Low Thermal Conductivity for Better Overall Fire Performance

Low thermal conductivity is another reason calcium silicate boards excel in fire-rated systems. By restricting heat transfer, they help reduce the temperature rise on the non-fire side of the partition. This contributes to a more effective barrier during a fire and improves energy efficiency during normal building operation.

Buildings that require both safety and energy management—such as schools, medical centers, logistics warehouses, and high-rise properties—can benefit greatly from this combination. A material with better insulation performance supports both structural protection and long-term operational efficiency.

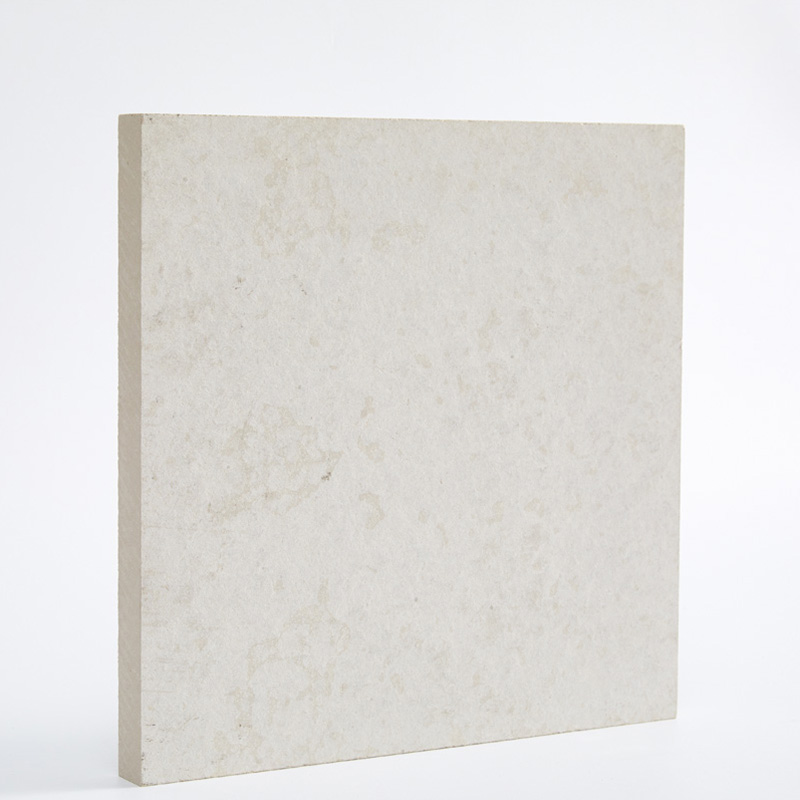

Dimensional Stability Under Varying Environmental Conditions

A reliable fire partition system depends on materials that hold their shape. New Element's calcium silicate boards are manufactured for dimensional stability, meaning they do not warp, swell, or shrink noticeably when exposed to humidity, temperature changes, or prolonged load.

This consistent form makes installation smoother and ensures the system performs predictably over time. For international projects with varying climates, this stability means fewer risks during shipping, storage, and construction.

Sizes Fit for Large-Scale Projects

To meet the needs of different commercial structures, New Element calcium silicate boards are available in widely used dimensions: 2440 mm × 1220 mm, 3050 mm × 1220 mm, and more customized sizes. These formats allow flexibility in designing large wall sections and ceilings with fewer joints, enhancing the overall integrity of the fire partition system.

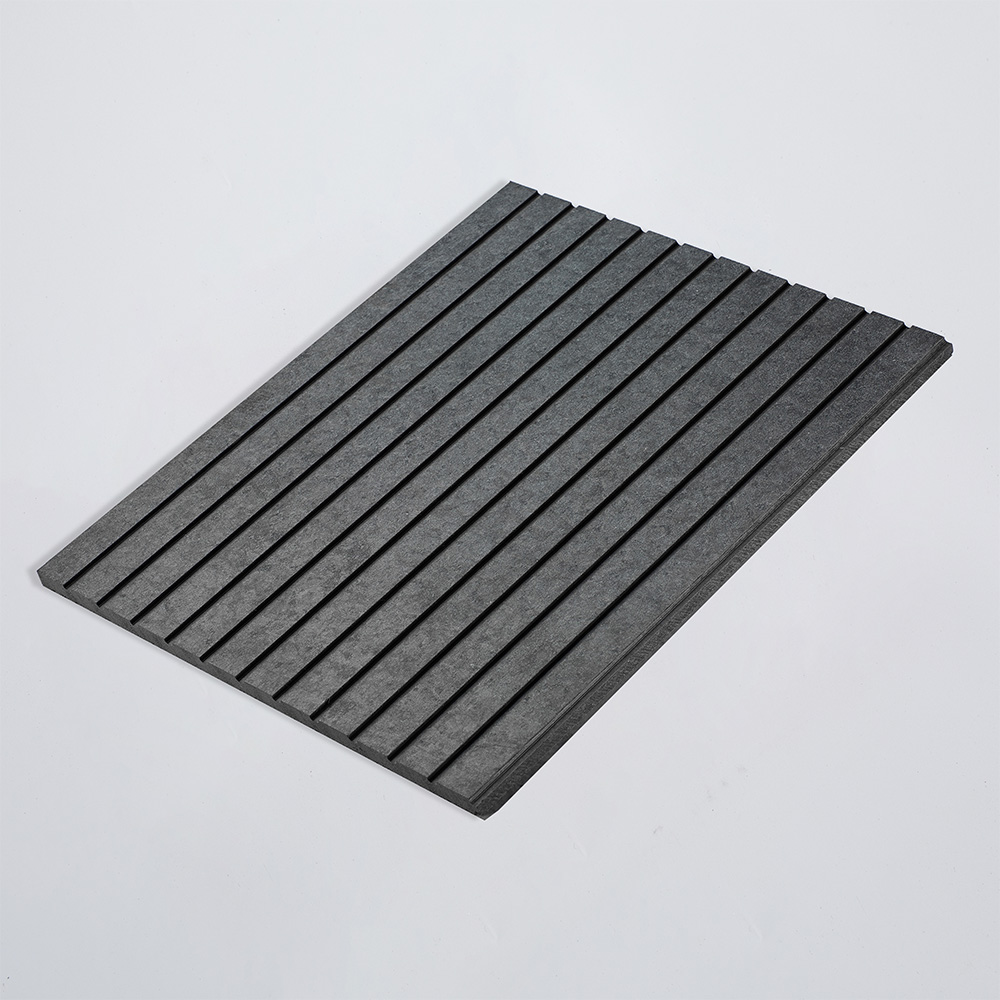

Calcium Silicate Boards For Fire Ceiling System

Why Calcium Silicate Boards Are a Strong Match for Commercial Projects

Commercial construction requires materials that support safety, efficiency, and long-term performance. Calcium silicate boards meet these demands by delivering:

• Strong fire resistance—Protects structures and occupants by slowing fire spread.

• Efficient installation—Lightweight and easy to handle, reducing labor time and costs.

• Durability against wear and pests—maintains integrity even in high-traffic or harsh environments.

• Reliable insulation properties—helps regulate temperature and energy use.

• Stable structure over time—minimizes warping, cracking, or deformation for long-term reliability.

When these qualities come together in a fire partition system, the result is a building with a higher level of fire safety and structural resilience.

For project owners and builders seeking dependable fire-rated solutions, calcium silicate boards, especially those engineered by New Element, offer a combination of performance and practicality that aligns well with modern building requirements. For more details or project inquiries, feel free to reach out to [email protected].