Fire protection inside a building’s ductwork system often gets overlooked, yet it plays a critical role in preventing flames and smoke from spreading through air channels. The materials surrounding these ducts determine how well a building performs under fire exposure and how quickly the fire can be contained.

Take New Element calcium silicate boards for ductwork systems as an example—these boards show how the right insulation solution can significantly upgrade safety performance without complicating installation or long-term maintenance.

Why Ductwork Fire Protection Matters

When a fire breaks out, air ducts can unintentionally support the movement of hot gases and smoke from one area to another. Without proper thermal insulation and fire-resistant linings, ducts may deform, collapse, or even become a direct pathway for fire. For this reason, fire-rated ductwork has become a priority in modern construction, especially in commercial buildings, industrial facilities, and large public structures.

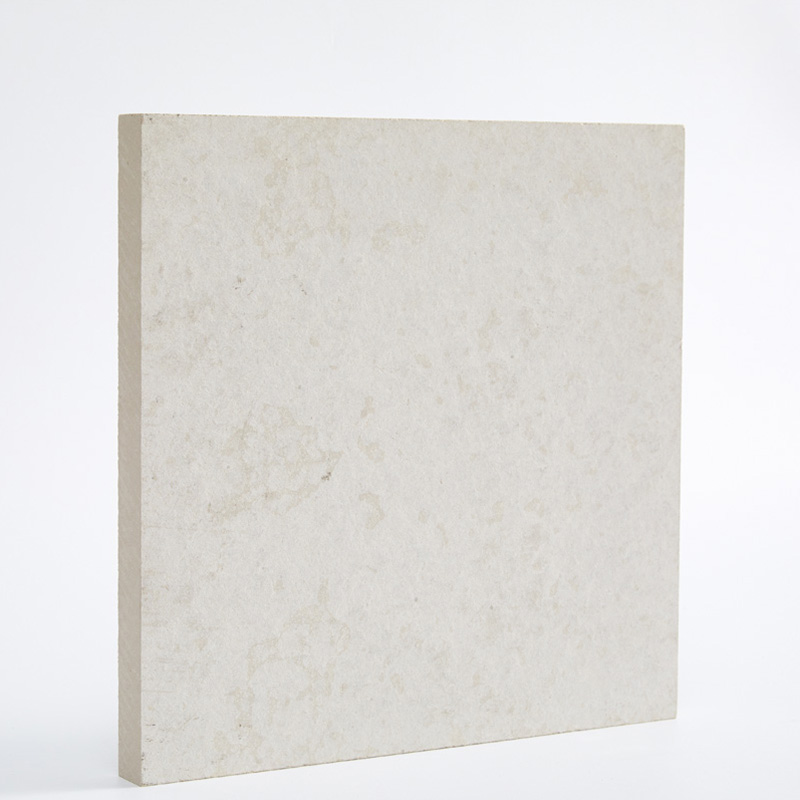

Calcium silicate board has become one of the preferred materials for this purpose thanks to its strength, stability, and fire-resistant properties. Beyond general insulation, its performance under sustained high temperatures makes it especially suited for duct systems that require reliability during critical conditions.

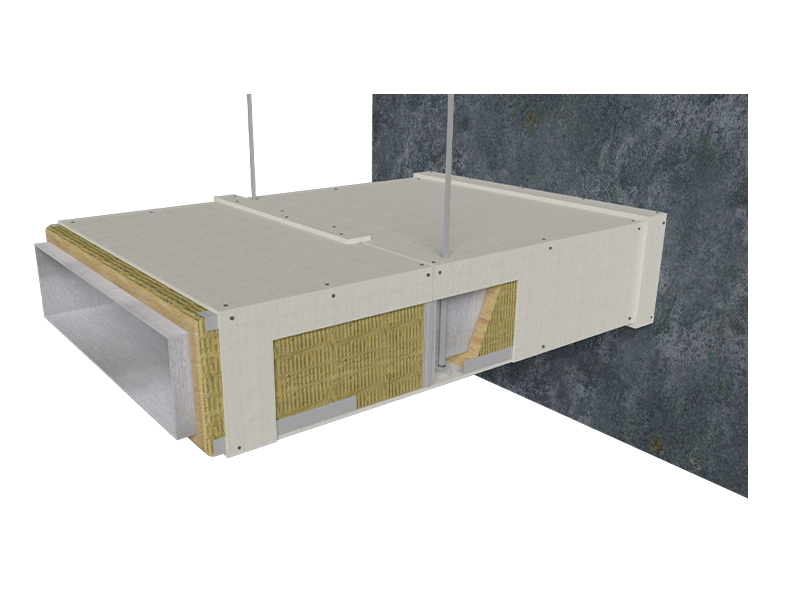

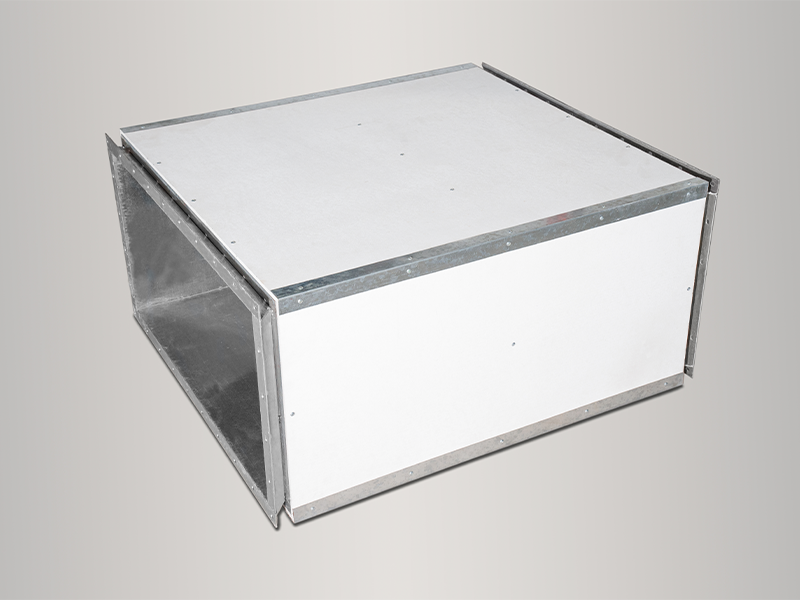

Fire-Rated Ductwork System

Why Calcium Silicate Boards Are Used in Ductwork Systems

Calcium silicate boards are engineered to resist extremely high temperatures while maintaining structural integrity. Their ability to act as a thermal barrier helps ductwork withstand fire exposure long enough to prevent flames from spreading to other areas. In real applications, this means fewer weak points and a more secure fire-rated ductwork system.

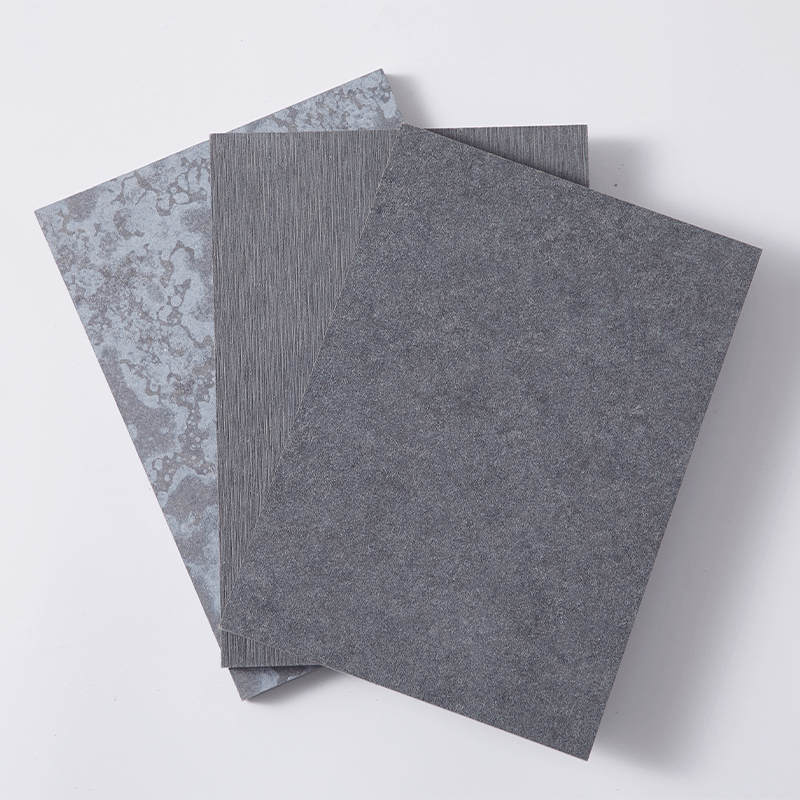

New Element provides calcium silicate boards specifically designed for ductwork applications, available in two standard dimensions—2440 × 1220 mm and 3050 × 1220 mm. These boards come in a range of thicknesses, including 9 mm, 10 mm, 12 mm, 15 mm, and 24 mm, giving builders flexibility to meet different fire protection levels and structural configurations.

Among the product lineup, Protectpan stands out as a low-density fire-rated calcium silicate board engineered for structural fire protection assemblies. These dimensions give contractors flexibility in designing ventilation shafts, kitchen exhaust ducts, smoke extraction ducts, and other fire-rated systems.

Key Performance Features: Enhance Fire Protection

1. High Temperature Resistance up to 1200°C

One of the most important performance indicators for fire-resistant materials is their behavior at extreme temperatures.

New Element’s calcium silicate boards are engineered to operate at temperatures up to 1200°C, which is far beyond the temperature range reached during most fire events. This allows ductwork to maintain shape and stability longer, and it provides a predictable response during emergency situations.

The extended heat tolerance also means the boards don’t crack, deform, or break apart under thermal shock—an essential requirement for kitchen exhaust ducts and industrial ventilation systems.

Fireproof Calcium Silicate Board Supplier

2. Low Thermal Conductivity for Stronger Thermal Insulation

The low thermal conductivity of calcium silicate board helps slow down heat transfer from one side of the duct to the other. This contributes to:

- better control of fire spread

- reduced thermal stress on surrounding structural elements

- improved insulation performance for both heating and ventilation systems

By minimizing heat transmission, a duct lined with these boards can serve as a reliable fire barrier.

3. Stable Dimensions Under Changing Conditions

Poor dimensional stability can compromise an otherwise good fire-protection design. Fire-resistant calcium silicate boards from New Element are manufactured to retain shape and size consistently, even when exposed to fluctuations in temperature or humidity.

For installers, this means the board will not warp, expand, or contract unpredictably—critical factors when creating airtight and continuous fire-resistant assemblies.

4. Durable and Mothproof for Long-Term Use

Ductwork systems often run through concealed areas of buildings where routine maintenance is difficult. Materials used in these areas must hold up over time without deteriorating.

New Element’s calcium silicate boards resist moisture, pests, and general wear. Their durability ensures that the fire-resistant properties of the ductwork system remain reliable year after year.

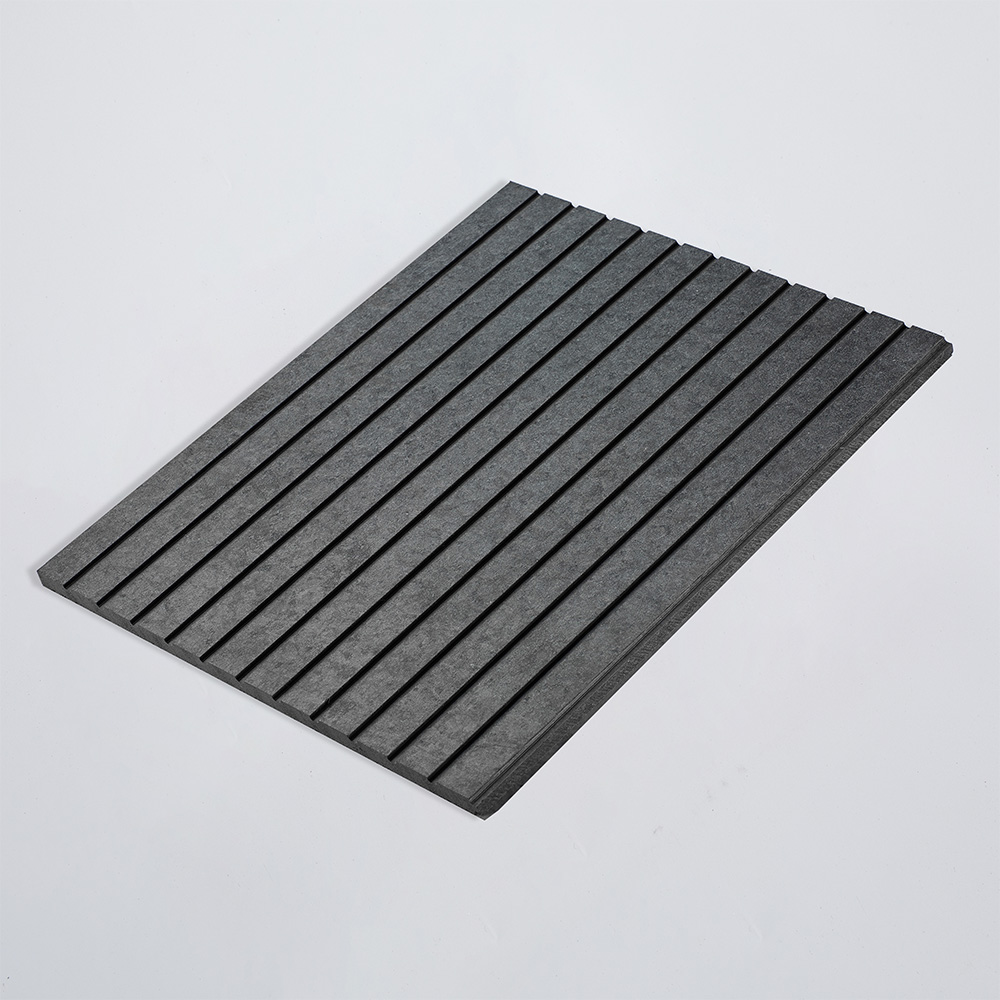

5. Lightweight and Easy to Cut for On-Site Installation

From a contractor’s perspective, ease of installation is a major advantage. The fireproof calcium silicate boards are lightweight enough to handle during elevated installations, and they can be cut cleanly on-site using common tools.

This reduces labor hours, speeds up project progress, and minimizes waste—practical benefits for large-scale commercial projects.

Calcium Silicate Board For Ductwork System

How These Features Improve Fire-Rated Ductwork Performance

When combined, the thermal and physical properties of calcium silicate boards create a ductwork assembly that can:

- contain fire for a longer period

- maintain structural integrity

- resist collapse or deformation

- reduce smoke transmission

- meet fire rating requirements for various ventilation and exhaust systems

This level of performance is essential for applications such as:

- smoke extraction ducts

- kitchen exhaust ducts

- pressurization ducts

- general HVAC systems in large facilities

Using high-quality fire-resistant materials also supports compliance with fire safety codes and helps building owners achieve safer environments with fewer long-term maintenance risks.

Final Word: A Practical Choice for Modern Construction Projects

As construction standards continue to evolve, builders and project owners place greater emphasis on fire protection within mechanical systems. Calcium silicate boards—from their fire resistance to their thermal insulation properties—play an increasingly important role in meeting these expectations.

New Element’s calcium silicate boards, engineered specifically for demanding fire protection applications, demonstrate how this material can strengthen ductwork performance without adding unnecessary complexity to the installation process. With a combination of high-temperature endurance, low thermal conductivity, and consistent dimensional stability, they provide a dependable solution for projects that require durable and fire-rated ductwork.

For more information or to discuss your project requirements, contact us at [email protected].