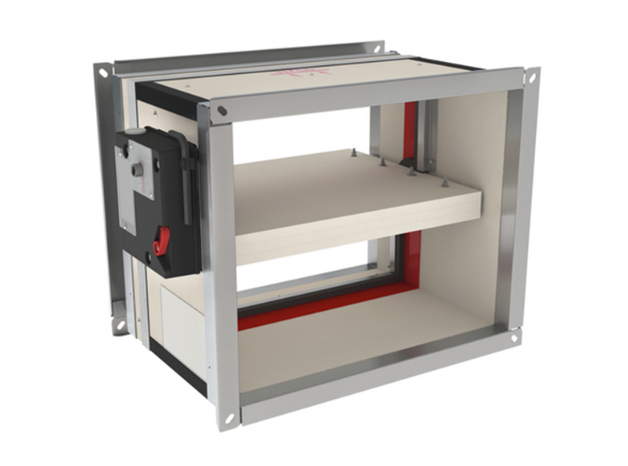

Fire damper systems are essential in preventing flames and smoke from spreading through HVAC ducts, safeguarding both occupants and property. The effectiveness of these systems relies heavily on the quality and properties of the materials used. Among these, calcium silicate boards have emerged as one of the most reliable options for fire protection due to their superior heat resistance, durability, and structural performance.

Understanding Fire Damper Systems

A fire damper system is a critical component of a building's passive fire protection strategy. Installed within HVAC ducts, fire dampers automatically close when the surrounding temperature reaches a predetermined threshold, usually around 165°C to 280°C, depending on design standards. By blocking the path of fire and smoke, they prevent the rapid spread of flames through ductwork, which is one of the most common routes for fire propagation in modern buildings.

Key factors influencing fire damper performance include:

• Response Time: The damper must activate quickly to contain the fire before it spreads.

• Material Integrity: Components, particularly the lining and closure mechanisms, must resist high temperatures without deformation or failure.

• Compatibility with HVAC Systems: Dampers should function without impeding normal airflow under non-emergency conditions.

Selecting the right material for the damper lining is therefore critical. Calcium silicate boards offer an optimal balance of heat resistance, mechanical strength, and ease of installation.

Fire Dampers For HVAC Systems

Why Calcium Silicate Boards Are Ideal for Fire Dampers

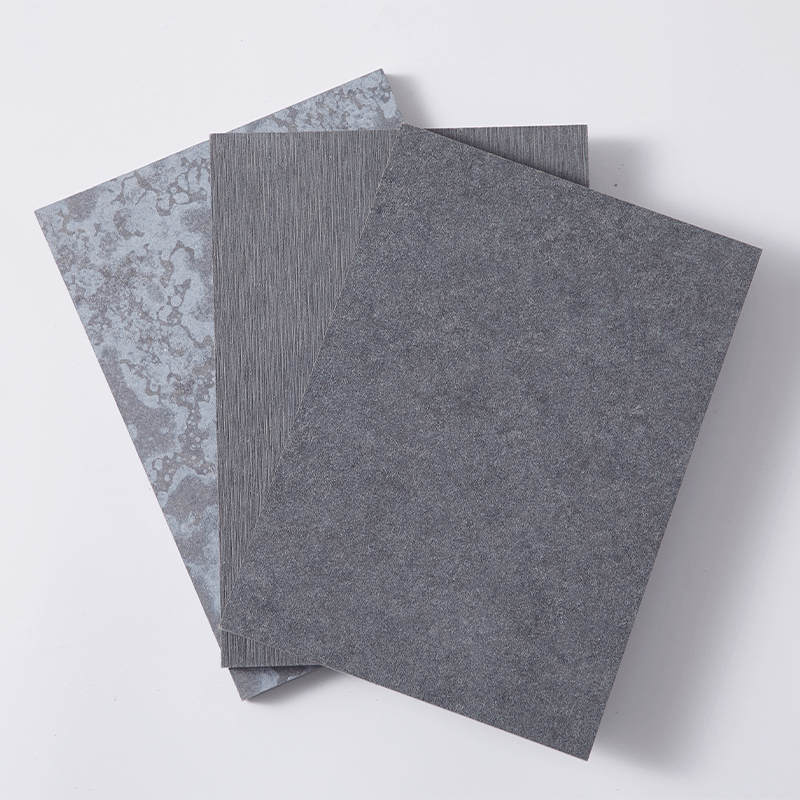

Calcium silicate boards are engineered to provide exceptional fire resistance while maintaining lightweight and workable properties. New Element’s calcium silicate boards, specifically designed for fire safety applications, provide several notable benefits:

1. High Temperature Resistance

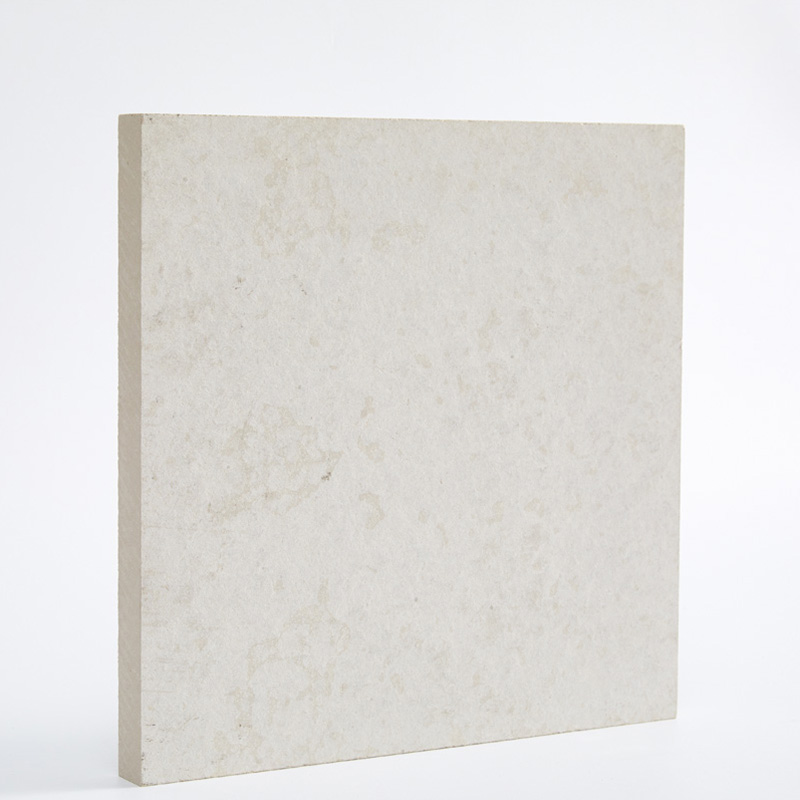

Calcium silicate boards can withstand temperatures up to 1200°C, far exceeding the capabilities of conventional materials like gypsum. This high resistance ensures that fire dampers remain operational even in extreme fire scenarios, providing critical containment in industrial facilities, commercial buildings, and high-temperature construction environments.

2. Lightweight and Easy to Cut

The boards’ lightweight nature simplifies transportation, handling, and installation. Contractors can cut them on-site to precise dimensions using standard tools, reducing labor time and costs. This flexibility is especially beneficial for large-scale projects with complex ductwork and custom-sized fire damper installations.

3. Durability and Pest Resistance

Calcium silicate boards resist impact, wear, moisture, and pests such as termites and moths. Unlike gypsum, which may deteriorate over time in humid conditions, these boards maintain structural integrity for decades, ensuring consistent fire protection throughout the building's lifespan.

Calcium Silicate Board Supplier in China

4. Low Thermal Conductivity

These boards limit heat transfer, helping to contain fire and maintain temperature stability in adjacent areas. This not only enhances fire containment but also contributes to overall energy efficiency, as HVAC systems operate under more stable thermal conditions during both normal use and emergencies.

5. Dimensional Stability

Advanced manufacturing techniques allow calcium silicate boards to retain precise dimensions under varying environmental conditions, including high humidity and temperature fluctuations. This stability guarantees reliable installation, consistent performance, and compatibility with international building standards.

Comparison with Other Fireproof Materials

Several materials are available for fire protection, but calcium silicate boards provide a unique combination of properties:

| Material | Heat Resistance | Structural Strength | Ease of Handling | Durability | deal Use |

| Gypsum Boards | Moderate | Medium | Easy | Moderate | Residential walls/ceilings |

| Mineral Wool Boards | High | Low | Difficult | High | Insulation, non-structural barriers |

| Intumescent Panels | Moderate | Low | Moderate | Moderate | Fire seals for openings |

| Calcium Silicate | Very High | High | Easy | Very High | Fire damper linings, industrial protection, high-temperature applications |

Calcium silicate boards outperform other materials in high-temperature resistance, structural rigidity, and long-term durability, making them ideal for critical fire safety components.

Applications in Fire Safety and Construction

Calcium silicate boards are widely used across industries where fire safety is paramount:

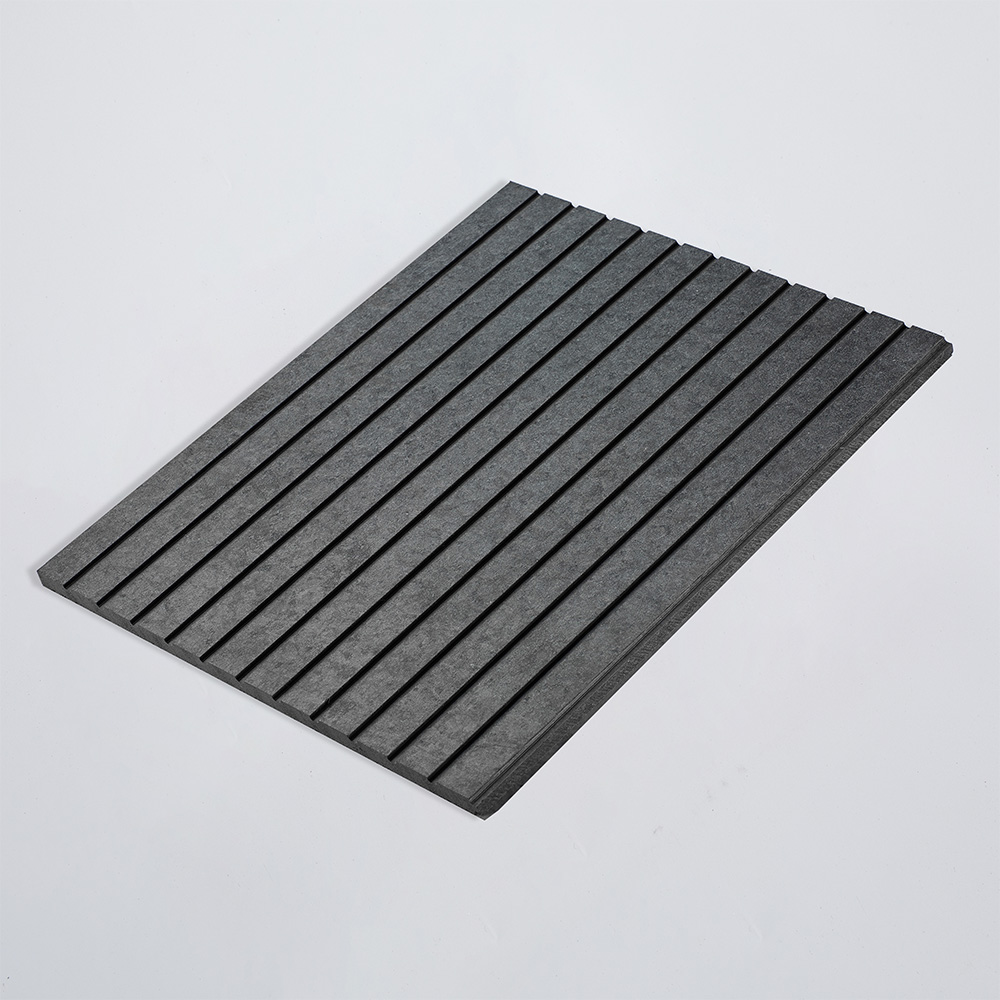

• Fire Damper Linings: Providing reliable barrier protection within HVAC systems.

• Industrial Fire Barriers: Suitable for power plants, chemical facilities, and factories with high fire risks.

• High-Temperature Construction: Areas exposed to heat, such as boiler rooms or furnace enclosures.

• Commercial and Residential Buildings: Walls, ceilings, and floors requiring enhanced fire resistance.

Their versatility makes them a top choice for any environment where reliable fire protection is required.

Calcium Silicate Boards For Fire Damper System

Conclusion

The selection of materials in fire damper systems directly impacts safety, performance, and longevity. Calcium silicate boards offer unmatched heat resistance, durability, and ease of installation compared to gypsum boards, mineral wool, or intumescent panels.

By integrating calcium silicate boards into fire damper systems, builders and engineers can ensure optimal fire containment, structural integrity, and long-term safety for both commercial and residential projects. For more information, technical support, or project inquiries, please contact us at [email protected].