Calcium silicate board and gypsum board are two prominent contenders in the vast field of construction materials, each offering unique attributes and applications. Their utility is paramount in the realm of construction, often serving as the backbone of various architectural structures. As a result, the choice of building material is a critical decision, as it directly influences the durability, safety, aesthetics, and overall longevity of any construction project.

Composition and Manufacturing

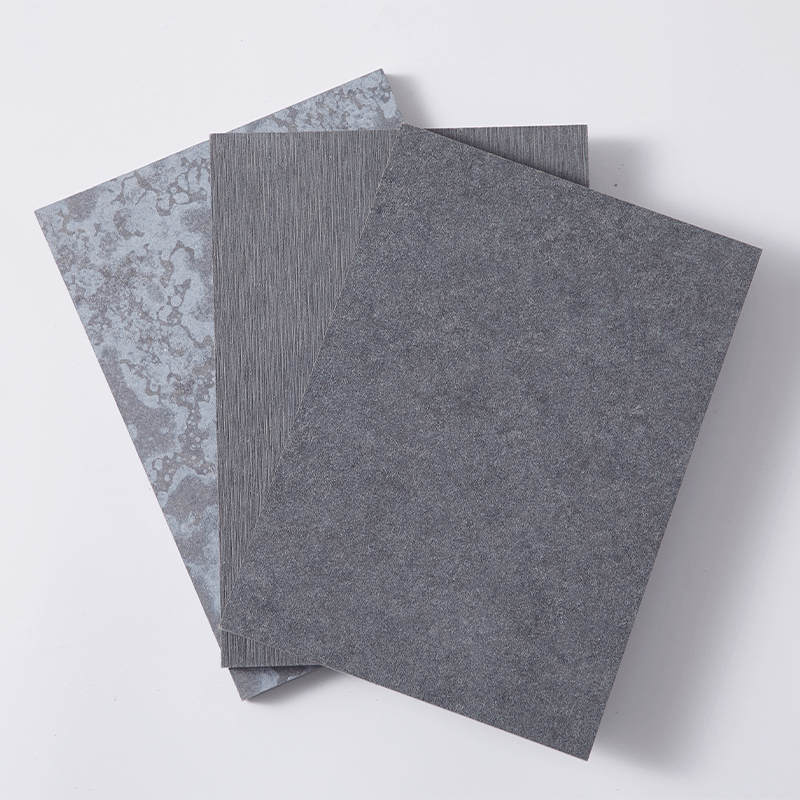

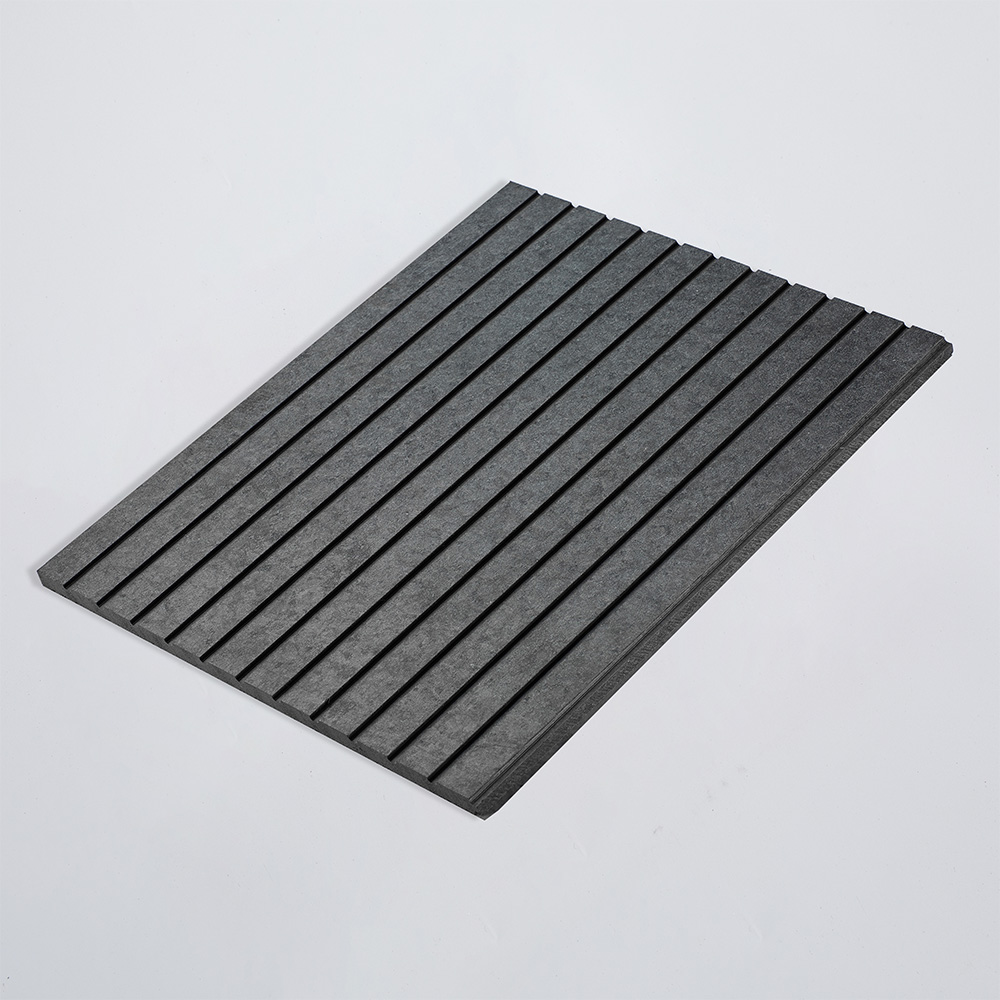

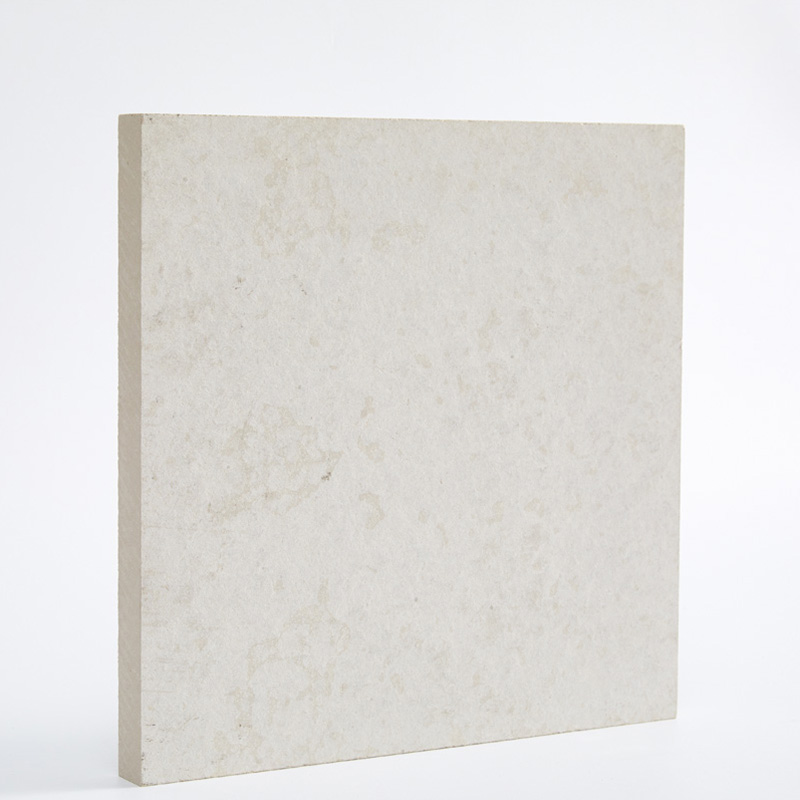

The calcium silicate board is composed of siliceous (sand-like) and calcareous (lime-like) materials, reinforced with fibers to increase structural integrity. The manufacturing process employs a high-pressure steam curing technique known as autoclaving. This method imparts the board with remarkable strength and durability, making it capable of withstanding significant wear and tear over an extended period.

Also known as plasterboard, gypsum board is made from gypsum, a naturally occurring mineral sandwiched between two thick sheets of paper. The production methods are also relatively straightforward, involving the hydration of calcium sulfate. The physical properties of the gypsum board, including its weight and thickness, contribute to its ease of handling and installation.

Calcium Silicate Board For Fire Protection

Durability and Performance

The longevity of calcium silicate board is one of their most appealing features, offering resistance to wear and tear that far surpasses many other construction materials. Their impact on structural stability is significant, providing a sturdy and reliable backbone to any construction project. Maintenance requirements are minimal, solidifying their position as a low-upkeep, long-term solution.

Gypsum board, on the other hand, is vulnerable to water damage and mold. This limitation can significantly impact the longevity and performance of the gypsum board in specific applications. Despite these challenges, the gypsum board is relatively easy to repair and maintain, making it a popular choice for many homeowners and builders. Yet, this need for regular maintenance can translate into additional costs and efforts as time goes on.

Applications in Construction

Calcium silicate board's versatility allows for its use in both interior and exterior applications, including wall lining, ceiling, and floor underlay, to name a few. Its resistance to high temperatures further broadens its applicability, making it an ideal choice for fire protection for tunnels, smoke ducting, and other high-heat environments prone to fire hazards. This heat resistance, coupled with its low moisture absorption, makes it a preferred option for wet areas such as bathrooms and kitchens, where dampness is a common issue.

Gypsum board, in contrast, finds its primary use in indoor applications. Its physical properties make it a good fit for wall and ceiling lining in dry environments. Nevertheless, as mentioned above, its susceptibility to moisture-induced damage limits its utility in damp areas. It may compromise its integrity over time, making it less versatile than the calcium silicate board.

Cost and Installation Considerations

While the initial cost of calcium silicate board can be more substantial than that of other materials, this investment is justified by its superior properties and durability. The complexity of its installation process may require professional assistance, adding to labor costs. However, considering its longevity and minimal maintenance requirements, these initial costs are often offset as time goes on.

Gypsum board is generally more affordable than calcium silicate board, making it a favored choice for budget-conscious projects. Its ease of installation, often manageable as a DIY project, further reduces overall project costs. However, it may lead to additional repair or replacement costs, potentially outweighing the initial savings.

Conclusion

Choosing between calcium silicate board and gypsum board involves careful consideration of various factors, including project requirements, budget, and environmental impact. Given its superior durability, versatility, moisture resistance, and long-term cost-effectiveness, the calcium silicate board emerges as the more reliable option.

As a premier calcium silicate board manufacturer in China, New Element is committed to offering quality calcium silicate boards and fiber cement boards that meet diverse construction needs. If you want more information about our products, please feel free to contact us at [email protected].