Fiber cement boards have steadily carved a niche in modern construction for their unrivaled durability, fire resistance, and aesthetic adaptability. From facade cladding to interior partitioning, these versatile panels offer a compelling alternative to traditional building materials.

With this surge in applications, a standardized understanding of available sizes—thickness, width, and length—has become crucial. Builders, architects, and project planners must navigate an often complex landscape of dimensions to ensure optimal performance and cost-efficiency.

Fiber Cement Board: What It Is and Why Size Matters

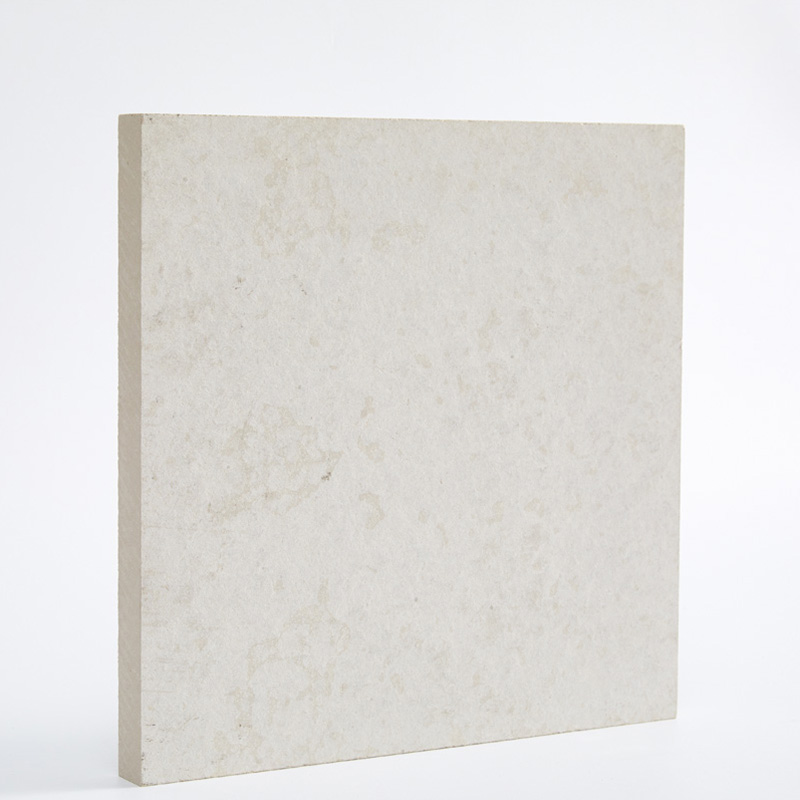

Fiber cement board is a high-performance composite building material made from cement reinforced with cellulose fibers, offering exceptional strength, dimensional stability, and resistance to rot, termites, and harsh weather.

Unlike gypsum or plywood, it does not warp, crack, or deteriorate under thermal stress, making it ideal for both interior and exterior applications such as tile substrates, decorative facades, and moisture-prone areas like kitchens and bathrooms.

When selecting fiber cement boards, understanding standard sizes is essential—whether you're cladding a high-rise facade or installing panels in wet environments, proper sizing ensures structural integrity, efficient installation, and reduced material waste.

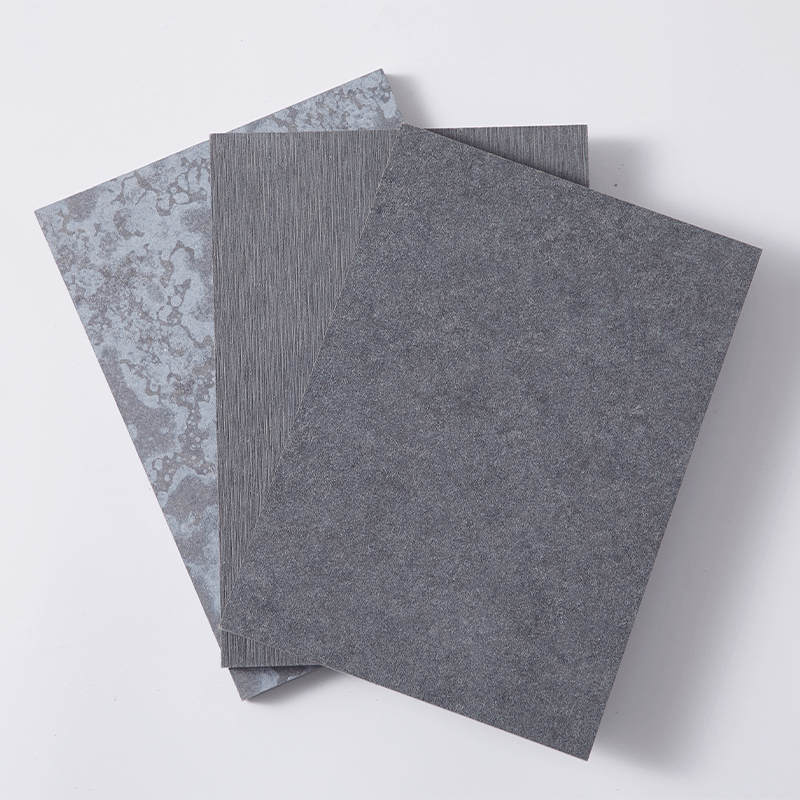

Waterproof Fiber Cement Partition & Ceiling Board

Standard Fiber Cement Board Thickness Options

The thickness of a fiber cement board determines its structural capacity and suitability for specific installations:

- 4mm to 6mm: These fiber cement boards are the lightweights in the range. Thin and nimble, they are typically used for ceiling panels, internal partition linings, and soffit boards. Their lightness makes them easier to install overhead or on non-load-bearing frames.

- 8mm to 12mm: This thickness range is the most commonly used and versatile option. Fiber cement boards in this thickness range are well-suited for exterior wall cladding, siding, and internal dry walls. They strike a balance between strength and workability, often selected for both residential and light commercial projects.

- 16mm to 25mm: These thick, heavy-duty fiber cement boards are reserved for industrial or commercial settings where high impact resistance is paramount. They’re often installed in high-traffic areas, machine rooms, or spaces demanding acoustic insulation.

Common Width and Length Dimensions

While thickness governs structural performance, width and length influence installation efficiency and material yield. The most common panel dimensions available in the global market include:

- Width: 900mm, 1,000mm, 1,200mm

- Length: 2,400mm, 2,440mm, 2,700mm, and up to 3,050mm in some regions

These dimensions are standardized to accommodate standard framing systems and transportation logistics. However, regional preferences may skew these figures. For instance, in North America, the 4'x8' (1,220mm x 2,440mm) format dominates, while in parts of Asia and Australia, a 3'x6' board is more typical for lightweight partitions.

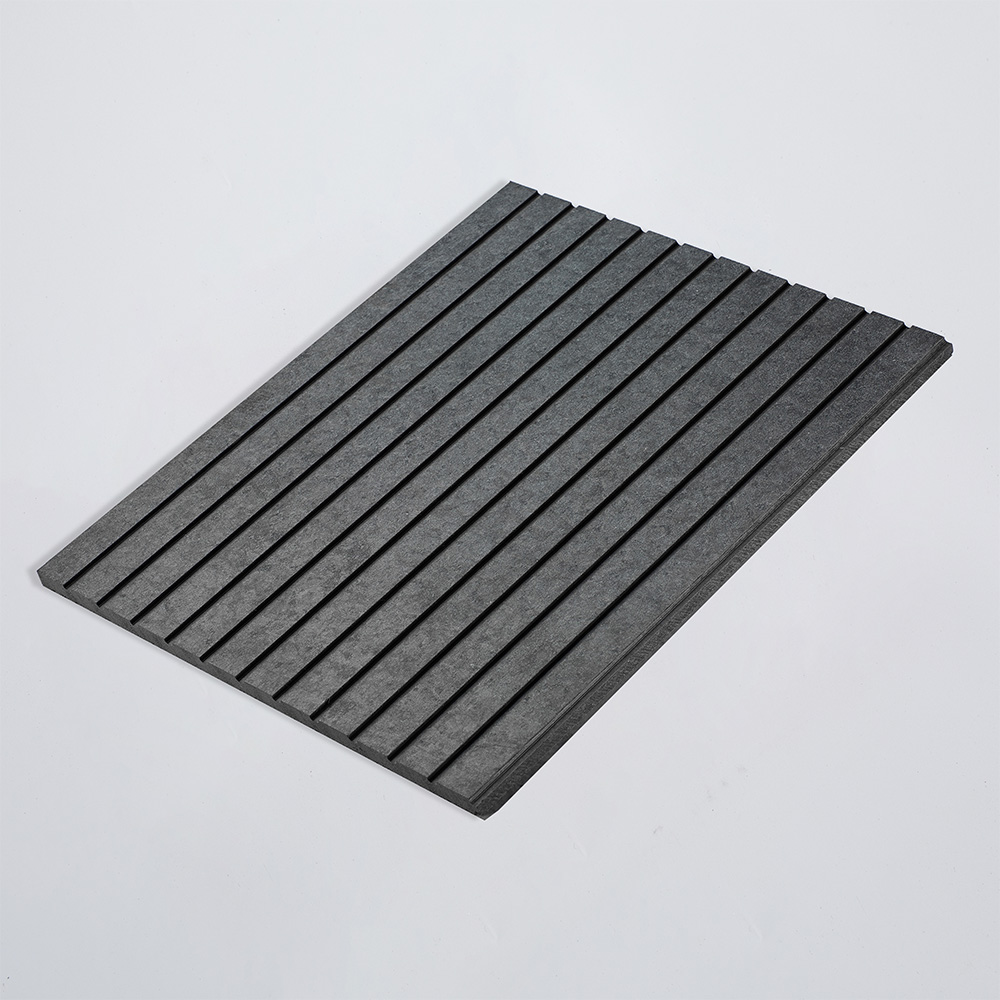

Wood Grain Fiber Cement Board Exterior Wall

Choosing the Right Size for Your Application

Selecting the appropriate fiber cement board size requires a multi-variable assessment:

Residential Projects: For homes, thinner boards are often preferred for ease of cutting and installation. Ceilings and wall partitions typically benefit from 6mm to 8mm panels, especially in multi-story dwellings where weight load is a concern.

Commercial Buildings: Heavier-duty panels (10mm and above) are recommended due to higher foot traffic and increased wear and tear. Cladding systems, especially those exposed to the elements, often require thicker boards paired with vapor barriers.

Additionally, aesthetics play a role. For facade applications, longer boards minimize joint lines and create a seamless appearance. Interior designers may prefer specific dimensions to align with spatial rhythm and modular furniture systems.

Custom and Specialty Sizes

Beyond the standard offerings, many manufacturers provide customization services to cater to bespoke architectural demands. These include:

- Cut-to-size boards: Pre-trimmed at the factory for immediate installation

- Oversized panels: Used in large-scale projects or feature walls

- Grooved or profiled edges: For joint concealment or decorative finishes

Opting for custom dimensions can enhance design precision and reduce on-site labor, but it comes with trade-offs. Lead times are typically longer, and costs may increase due to lower production volumes or additional tooling.

Final Thoughts

Understanding fiber cement board dimensions is crucial when planning for performance, installation ease, and cost control. Whether you need ceiling panels, wall cladding, or robust underlayments, the fiber cement board size you choose will impact everything from visual outcome to long-term durability.

If you're sourcing for a large-scale building project or looking for tailored fiber cement board solutions, reach out to New Element—a trusted fiber cement board manufacturer in China with deep expertise and full custom support.

Contact us at [email protected] to request samples, pricing details, and expert recommendations tailored to your project specifications.