Fiber cement decking is becoming popular for homeowners, builders, and commercial projects due to its durability, low maintenance, and aesthetically pleasing appearance. Unlike traditional wood decking, fiber cement is resistant to rot, pests, and harsh weather conditions, making it an excellent long-term investment.

However, like any construction material, improper installation can lead to costly repairs and maintenance. Sometimes, even skilled contractors can make crucial errors that compromise performance and longevity. In this article, we'll go over the common mistakes people make when installing fiber cement decking and provide practical solutions to ensure your decking is installed properly for maximum performance.

1. Ignoring Manufacturer's Instructions

One of the most common mistakes people make is not following the manufacturer's installation instructions. While this may seem like a minor oversight, it can have significant consequences. Fiber cement decking is designed with specific installation guidelines to ensure its longevity and performance. Skipping or misunderstanding these guidelines can lead to improper spacing, incorrect fastener types, and issues with ventilation or moisture.

Solution: Always read and follow the manufacturer's instructions thoroughly before starting the installation. Take note of important details such as the recommended spacing between boards, the type of fasteners to use, and ventilation requirements. Additionally, consider contacting the manufacturer if you have any doubts about the installation process.

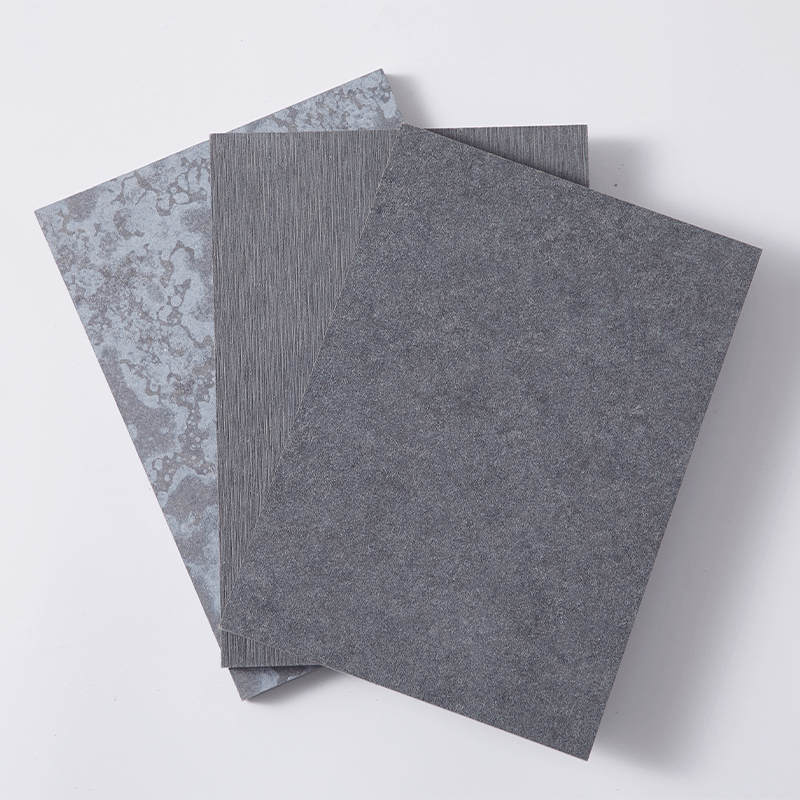

Top Fiber Cement Decking Manufacturer in China

2. Incorrect Substructure Support

The substructure or frame beneath your decking plays a crucial role in its overall stability. If the substructure is not adequately supported, fiber cement decking can sag or warp over time. It's vital to ensure that the joists are spaced correctly, and the foundation is solid enough to support the decking material.

Solution: For fiber cement decking, ensure that the framing is constructed with high-quality materials and that the spacing between joists is compliant with the manufacturer's recommendations. Typically, joists should be spaced about 3000mm apart, but this can vary depending on the specific fiber cement product you're using. Additionally, make sure the foundation is level and stable to prevent shifting that could affect the decking's structural integrity.

3. Using Incorrect Fasteners

Fiber cement decking requires the use of specific fasteners that are designed to handle the unique properties of the material. Using standard wood screws or nails can lead to problems such as corrosion, poor grip, and eventual failure of the decking. Choosing the wrong fastener can significantly shorten the lifespan of your decking.

Solution: Use fasteners that are specifically designed for fiber cement deckings, such as corrosion-resistant screws or clips. Stainless steel or galvanized screws are typically the best choice, as they resist rust and corrosion from exposure to moisture and the elements. Avoid using regular wood screws or nails, as these can damage the decking material and result in costly repairs.

Fiber Cement Board Accessories

4. Improper Expansion Gaps

One of the advantages of fiber cement decking is its ability to expand and contract with changes in temperature and humidity. However, if the expansion gaps between the boards are too narrow, the decking can become warped, cracked, or otherwise damaged. On the other hand, if the gaps are too wide, the decking may look uneven or unsightly.

Solution: Follow the manufacturer's recommendations for the correct gap size between decking boards. Generally, a gap of 40mm is ideal, but this can vary depending on the specific product. The goal is to allow for natural expansion and contraction without compromising the appearance or functionality of the deck. Using spacers can help maintain consistent gaps throughout the installation process.

5. Improper Moisture Management

Fiber cement decking is designed to withstand moisture, but improper moisture management can lead to problems. Without proper ventilation and drainage, moisture can get trapped under the decking, leading to mold growth, rot, or warping. Moisture build-up can also weaken the substructure and compromise the integrity of the entire deck.

Solution: Ensure that your decking is installed with adequate ventilation to allow air circulation and moisture escape. This can be achieved by installing a gap between the decking and the substructure, using breathable membranes, or creating a drainage system that allows moisture to flow freely away from the deck. Regularly inspect your decking for signs of moisture accumulation and take prompt action if you notice any issues.

6. Not Sealing the Ends of the Decking Boards

The ends of fiber cement decking boards are particularly vulnerable to moisture infiltration. If left unsealed, the ends can absorb water, which can lead to swelling, cracking, or even degradation of the material. It's important to protect the ends of your decking boards to ensure their longevity.

Solution: After cutting or trimming your fiber cement decking boards, apply a suitable end-sealant to the exposed edges. This helps to protect the material from moisture damage and ensures that the boards maintain their integrity over time. Be sure to use a sealant that is compatible with fiber cement and follow the manufacturer's recommendations for application.

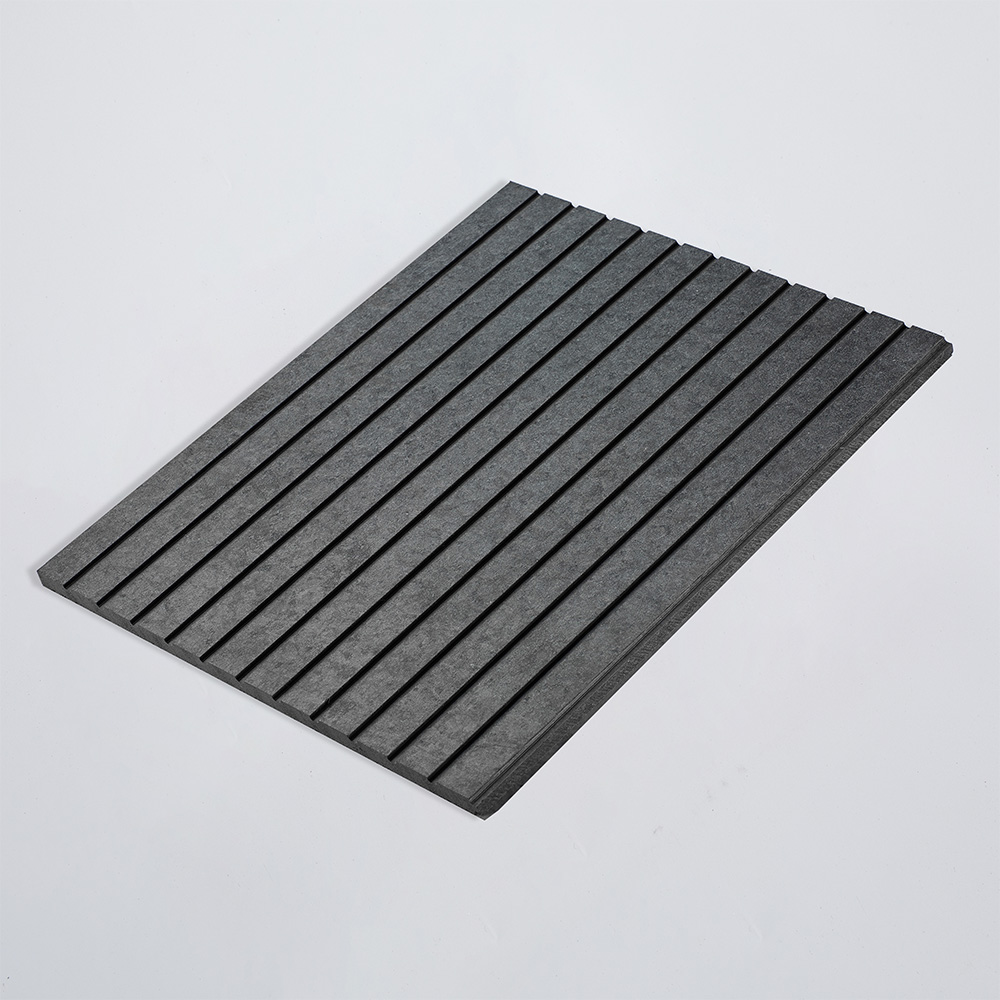

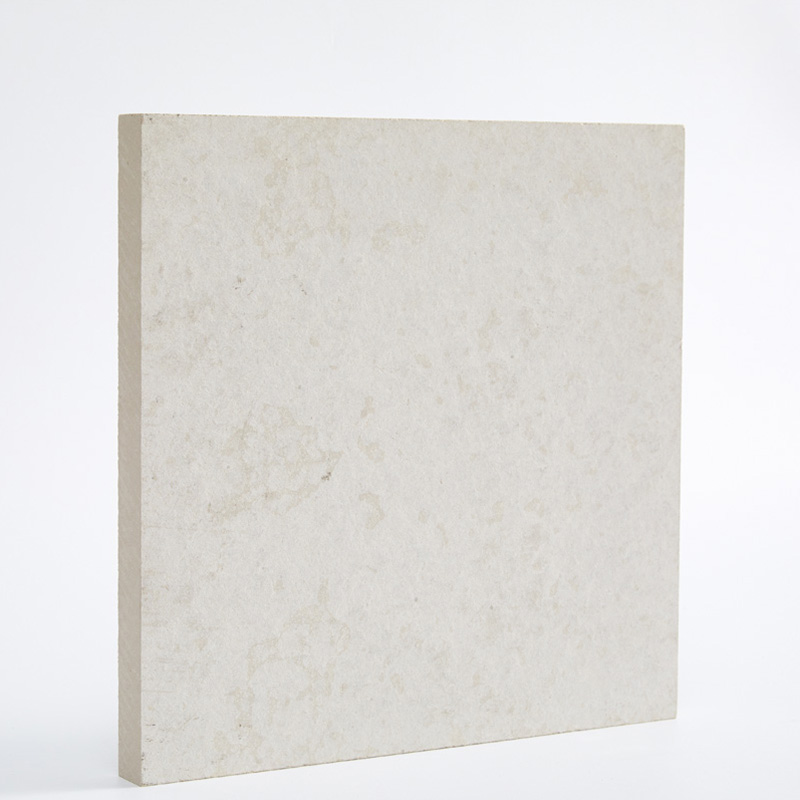

Fiber Cement Decking Applications

7. Poorly Executed Cutting and Drilling

Cutting or drilling into fiber cement decking can be a tricky task. Incorrect methods or tools can cause the material to crack, chip, or even break. Furthermore, using the wrong saw blade or drill bit can lead to rough edges that can be difficult to finish.

Solution: Use the proper tools for cutting and drilling fiber cement decking. A carbide-tipped blade on a circular saw or a diamond blade for cutting is recommended. For drilling, use a masonry or carbide-tipped drill bit. Always wear protective gear like safety glasses and a dust mask to protect yourself from the dust generated during the cutting process.

8. Skipping Regular Maintenance

While fiber cement decking is low maintenance compared to wood, it still requires regular upkeep to maintain its appearance and function. Skipping periodic cleaning or inspections can lead to the accumulation of dirt, debris, and moisture, all of which can cause damage to the decking over time.

Solution: Clean your fiber cement decking regularly to remove dirt, leaves, and other debris. This will prevent moisture from being trapped and reduce the likelihood of mold or mildew growth. Additionally, inspect the deck annually for signs of wear or damage and make necessary repairs promptly. Sealing the decking every few years can also help maintain its appearance and protect it from the elements.

Conclusion

Fiber cement decking offers exceptional durability, fire resistance, and low maintenance requirements when installed correctly. By avoiding these common installation mistakes, you can ensure your commercial or high-end residential project delivers maximum value and performance for decades.

With over two decades of expertise in manufacturing high-quality fiber cement products, New Element offers fiber cement decking solutions that have been used in landmark projects worldwide. Our technical team is available to provide detailed installation guidance for your specific project requirements, ensuring optimal performance in any application.

When properly installed and maintained, fiber cement decking represents one of the most promising and sustainable options on the market today, offering the perfect balance of durability, aesthetics, and value for commercial and premium residential applications. Explore more premium fiber cement boards from New Element!