Dry areas, whether in commercial, residential, or specialized settings such as laboratories, demand careful consideration in construction to ensure optimal functionality and durability. In such environments, the choice of building materials plays a crucial role in maintaining the desired conditions and ensuring long-term performance.

All About Fiber Cement Board Partition & Ceiling

Composition and Manufacturing Process

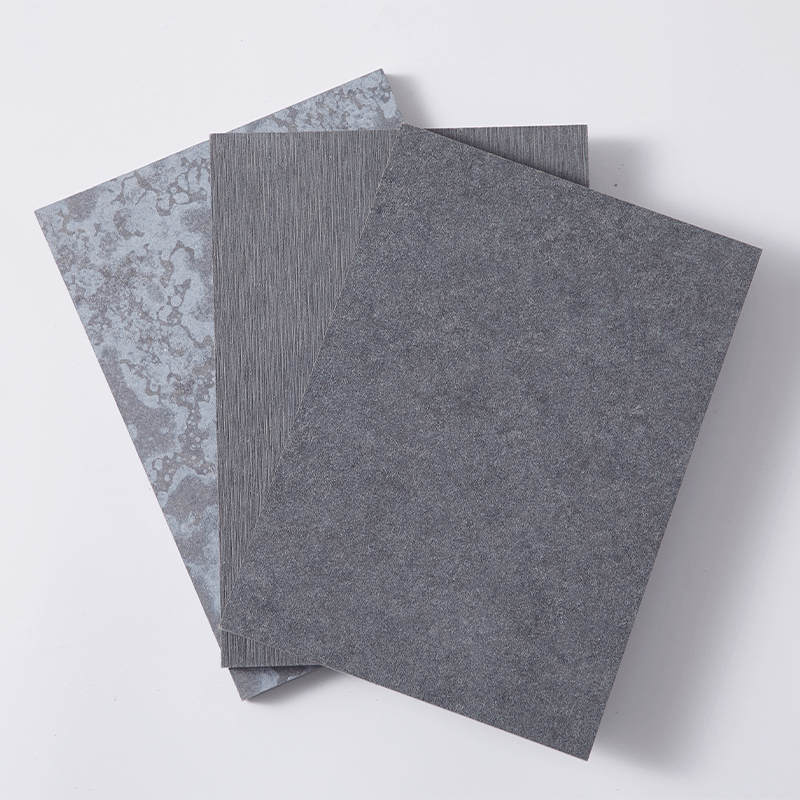

Fiber cement board, a versatile building material, emerges as a preferred choice for partitions and ceilings in dry areas. Cement, the primary component, provides strength and stability, while cellulose fibers enhance flexibility and resilience. Inorganic materials, like silica, are incorporated to improve specific properties like moisture resistance and fire retardancy.

During production, the mixture undergoes rigorous compression and curing stages, ensuring uniformity and structural integrity in the final product. As a result, fiber cement board boasts remarkable attributes such as its lightweight nature and ease of installation, making it an efficient solution for partition systems.

Cost-Effectiveness and Longevity

Investing in fiber cement board partitions and ceilings translates into long-term value and peace of mind. Compared to traditional materials that may entail complex assembly procedures or frequent upkeep, fiber cement board partitions and ceilings offer a hassle-free alternative, reducing labor costs, downtime, and overall project expenses while maximizing return on investment.

Utilizing Fiber Cement Board Partition Systems

Robustness and Durability

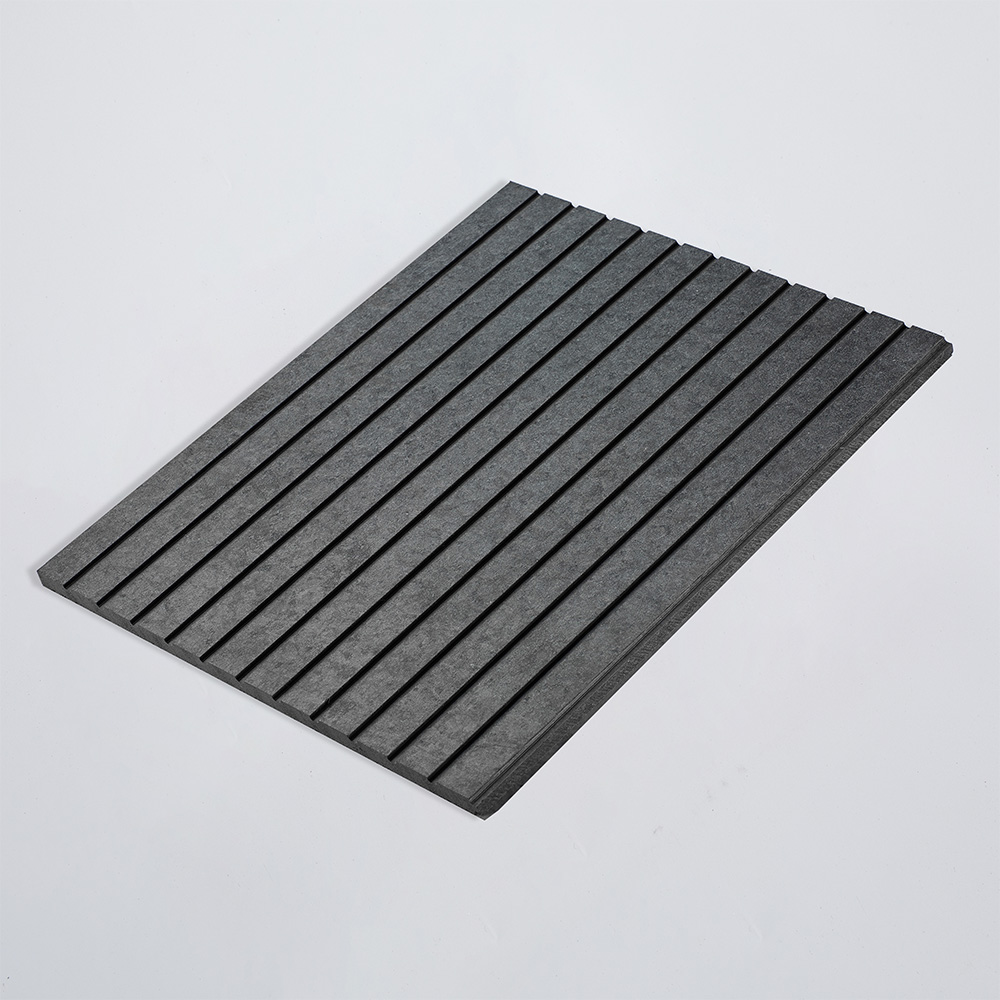

Engineered for longevity, fiber cement board partitions exhibit impressive durability in harsh conditions. It withstands impact, abrasion, and weathering to ensure reliable performance over extended periods. That means these partitions maintain their structural integrity and aesthetic appeal over time, helping to minimize the need for costly repairs or replacements.

Lightweight Construction

Despite its robust composition, fiber cement board partitions remain surprisingly lightweight. This attribute reduces the structural load on buildings, enabling more flexible design options and potentially lowering construction costs. On the other hand, the lightweight nature also simplifies handling during transportation and installation. Unlike heavier materials that require specialized equipment or extensive workforces, fiber cement board partitions can be easily maneuvered into place, reducing labor costs and accelerating project timelines.

Versatile Applications

The versatility of fiber cement board partitions extends beyond conventional office spaces to encompass various settings with diverse functional requirements. From open-plan work environments and conference rooms to specialized areas like laboratories, clean rooms, or manufacturing facilities, fiber cement board partitions adapt effortlessly to different spatial configurations and usage demands, enhancing both functionality and aesthetics.

Enhancing Dry Area Spaces with Fiber Cement Board Ceilings

Low Thermal Conductivity

Fiber cement board ceilings contribute to energy efficiency by minimizing heat transfer between indoor and outdoor environments. Their low thermal conductivity helps regulate interior temperatures, reducing reliance on heating and cooling systems and lowering overall energy consumption, thus promoting sustainability and cost savings over the building's lifecycle.

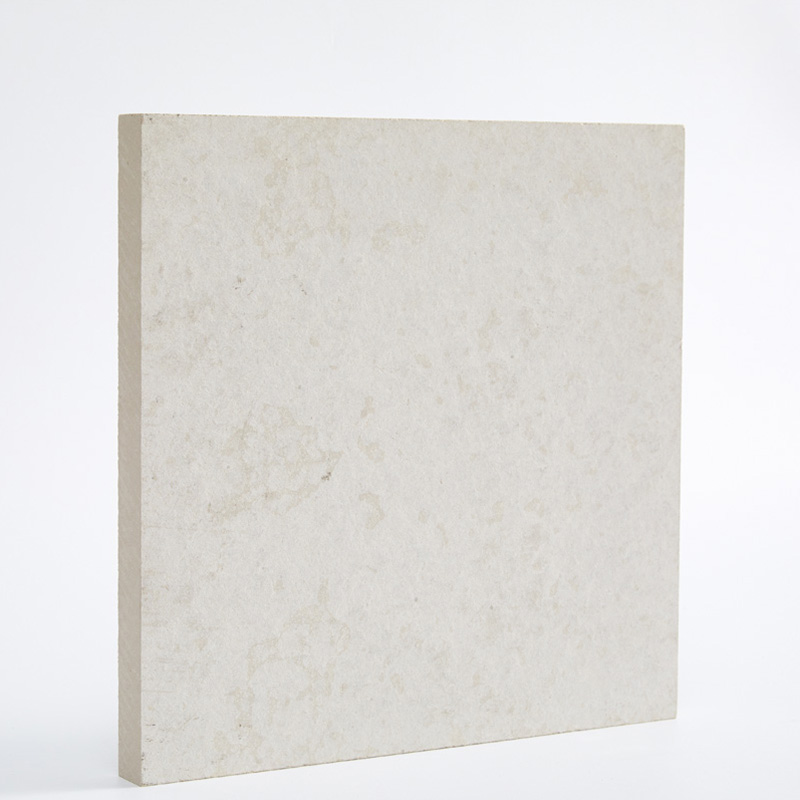

Antiseptic Properties

Unlike traditional materials like wood or gypsum, fiber cement board comes with exceptional resistance to moisture and does not swell, warp, or degrade when exposed to moisture, making it an ideal choice for environments prone to humidity or occasional water exposure.

Moreover, thanks to its inorganic composition, fiber cement board ceilings are inherently resistant to mold, mildew, fungal and microbial growth. This property contributes to a healthier indoor environment and facilitates compliance with stringent sanitation standards, such as laboratories, clean rooms, healthcare facilities, food processing plants, residential bathrooms, etc.

Integration with Lighting and HVAC Systems

Fiber cement board ceilings provide a versatile platform for integrating lighting fixtures, HVAC ducts, and other mechanical systems. Their sturdy construction and customizable designs accommodate various installation requirements, ensuring seamless integration without compromising aesthetic appeal or performance. By strategically positioning lighting and HVAC elements within the ceiling structure, designers can optimize space utilization, improve indoor air quality, and enhance occupant comfort and productivity.

Conclusion

Fiber cement board partition and ceiling solutions present a compelling option for enhancing dry area environments. Their unique properties and versatile applications make them well-suited for various settings, from commercial buildings to specialized facilities requiring stringent hygiene standards.

By choosing high-performance fiber cement boards, construction professionals can ensure not only superior performance but also cost-effectiveness and longevity, ultimately creating spaces that are both functional and sustainable.